A Comprehensive Guide to Acoustical Metal Roof Decking

Are you preparing a bid and the design drawings call for acoustical metal decking? If so do not make the assumption that it is just standard metal decking.

Acoustical metal decking is a special type of metal deck. It isn’t a standard stock item that you will find readily available by your metal deck supplier.

Western Metal Deck has supplied metal decking for over 30 years. We have assisted many of our customers throughout the years who bid or won a job with acoustical metal decking but didn’t really know what they were getting into. We will help you understand what acoustical metal decking is and why it is important.

In this article we will cover:

- What Is Acoustical Metal Decking?

- How Does Acoustical Metal Decking Work?

- When Should You Use Acoustical Metal Deck?

- Non-Cellular Acoustical Metal Decking

- Cellular Acoustical Metal Deck

- Cellular Vs Non-Cellular Acoustical Metal Deck

What Is Acoustical Metal Decking?

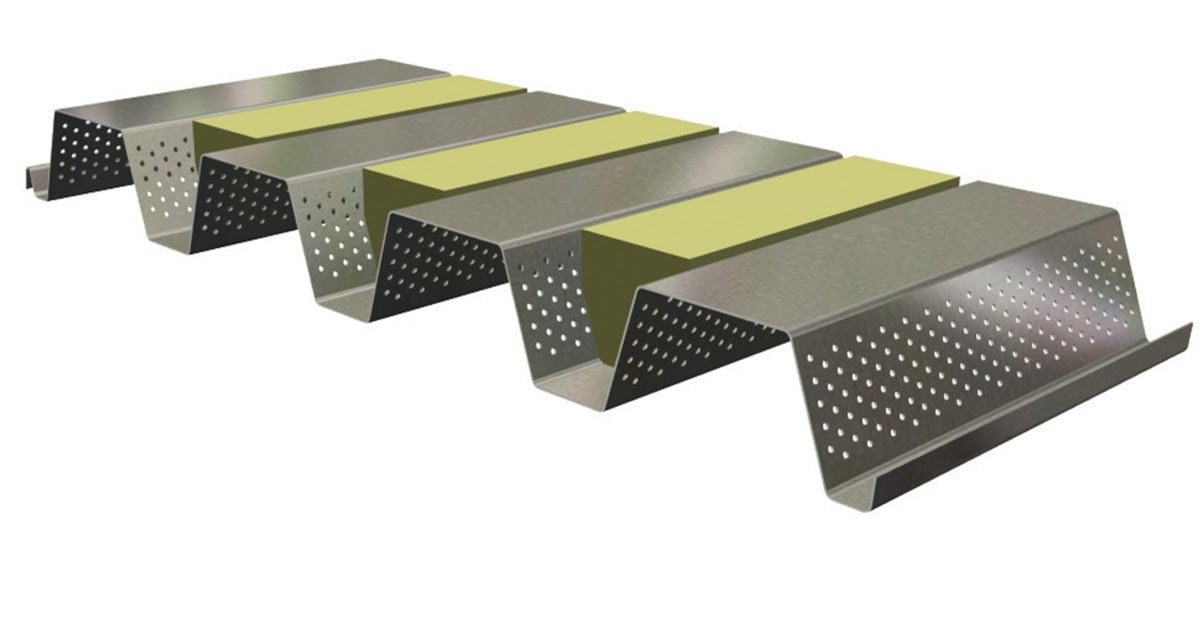

Acoustical metal decking will have small perforated holes in the flutes of the decking or along the cellular plate located at the underside of the panel. Sound-absorbing insulation batts will be placed within the flutes of the metal deck and will cover the holes. It’s designed to decrease the noise from below.

How Does Acoustical Metal Decking Work?

The noise from within the building will travel through all of the tiny perforated holes of the acoustical metal decking. The sound is then absorbed by the insulated batts that cover all of these holes. The insulated sound absorbing batts reduce the sound in a room by dampening the reverberation off of the steel decking.

When Should You Use Acoustical Steel Decking?

Acoustical steel decking is used when you have a building where the noise needs to be lessened. It’s designed to be a sound absorbing ceiling and a structural metal roof deck.

Acoustical decking is used when you have a project that requires a reduction in noise such as: auditoriums, sporting arenas, theatres, laboratories, classrooms, restaurants, and other structures where exterior noise could be a problem.

There are two methods to achieve this. The first method is to use non-cellular acoustical metal decking. The other is to use cellular acoustical metal decking.

What Is Non-Cellular Acoustical Metal Decking

Non-cellular acoustical metal decking has perforated metal holes in the flutes and sound-absorbing insulation batt strips inserted into the flutes from the topside. It is a better option for an industrial type setting where you are trying to lower the noise in a factory and you don’t mind looking up and seeing the bottom of the decking profile.

Types Of Non-Cellular Acoustical Metal Decking

Non-cellular acoustical metal decking is available in 1 ½” deep and 3” deep fluted roof decks. These panels come in 22, 20, 18, or 16 gauge. You have several finishes available: Galvanized, or both Galvanized and Prime Painted Grey or White on the bottom.

1 ½” Deep Type B

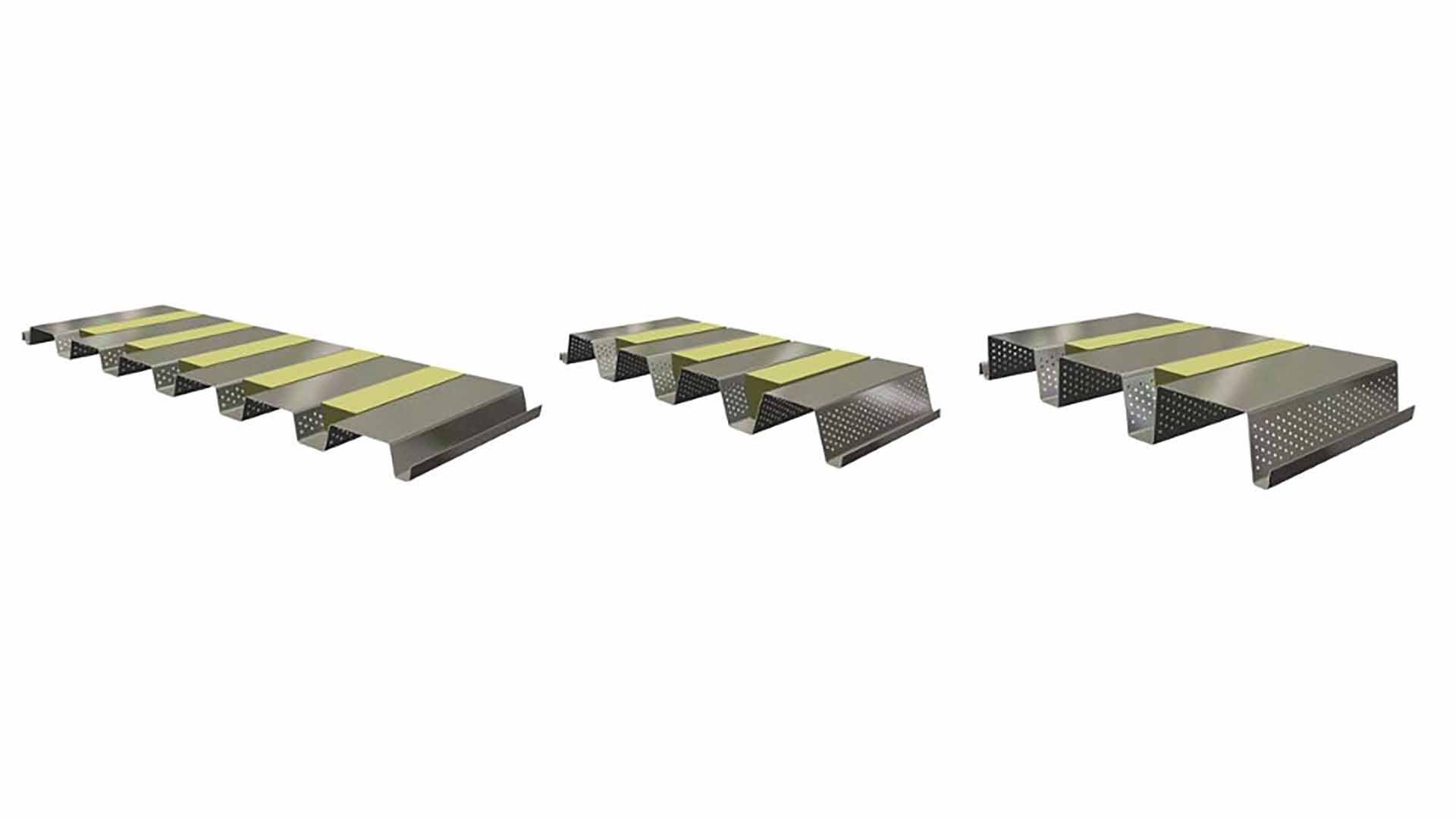

The most popular type of non-cellular acoustical metal decking is type B. Depending on its sidelap connection type B acoustical is also referred to as: HSB-36 AC, PLB-36 AC, or HSB-36-SS AC.

It is normally used on spans of approximately 8’-0” on center with a three-span condition.

3” Deep Type N

There are 2 types of 3” deep N deck panels available. These panels can span up to 18’ depending on the load and diaphragm shear.

Verco type N-24 acoustical can be referred to as either type N-24 AC, PLN-24 AC, or N-24-SS AC, depending on its sidelap connection. This panel is 2’-0” wide with the cell flutes at 8” on center.

Type HSN3-32 acoustical is referred to as either type HSN3-32 AC, PLN3-32 AC, or HSN3-32-SS AC, depending on its sidelap connection. This panel is 2’-8” wide with the cell flutes at 8” on center.

Installation of Non-Cellular Acoustical Metal Decking

Non-cellular acoustical metal roof deck is installed similarly to standard metal roof deck. The metal deck is spread and fastened to the steel frame.

Prior to installing the rigid board insulation and built-up roofing, the roofing crew installs the sound-absorbing insulation batt strips on the top side of the metal decking flutes. It is important to do it in this order, otherwise the sound batts can be easily blown away or destroyed by the elements if done ahead of time.

Lead Time

If the coil is in stock, in the right finish and already perforated, the lead time would be approximately 6 weeks. If the coil was in stock but not perforated, then the lead time would be approximately 8-12 weeks. It is always good to check the current lead time prior to committing to a schedule.

What Is Cellular Acoustical Metal Decking?

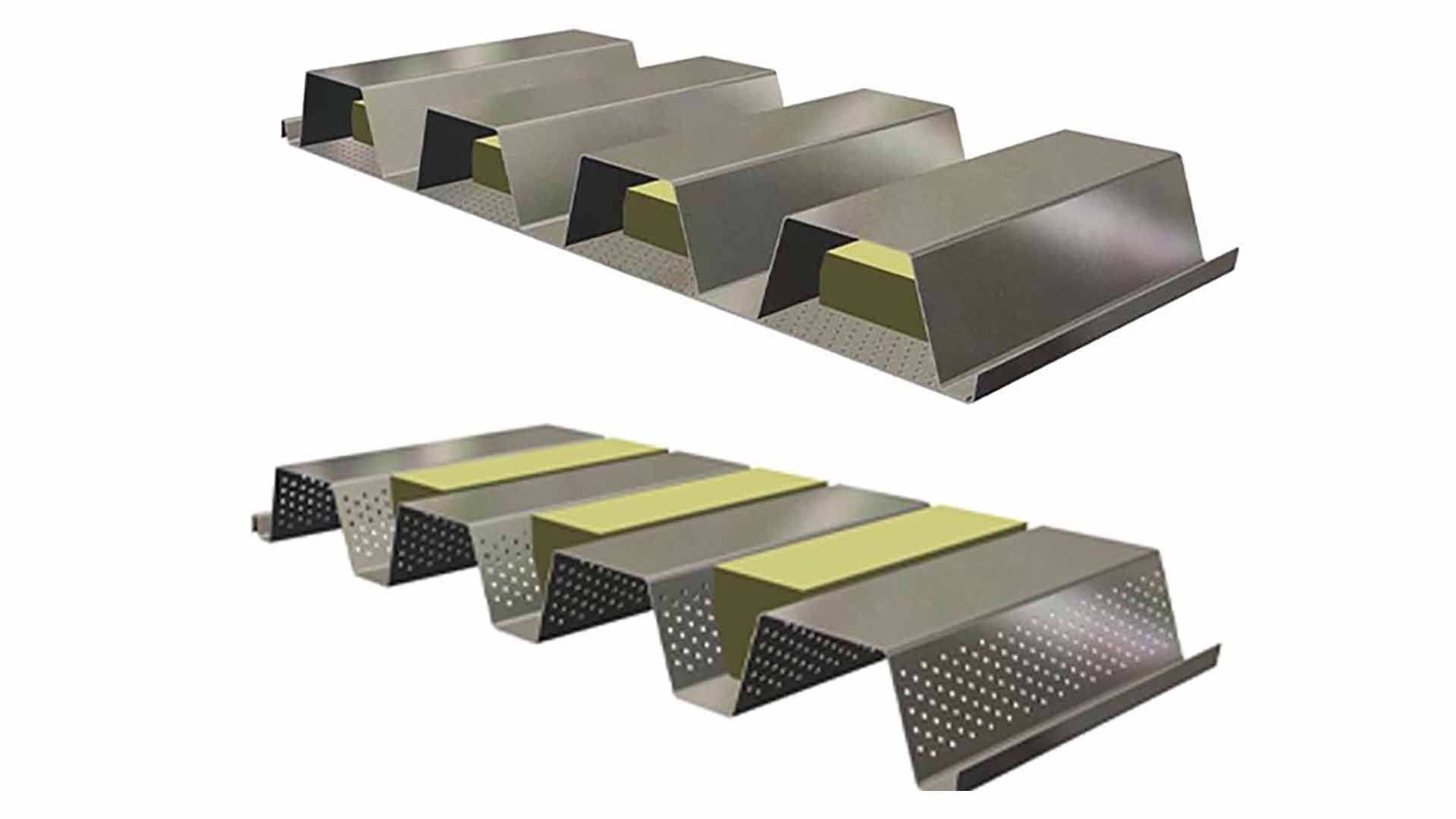

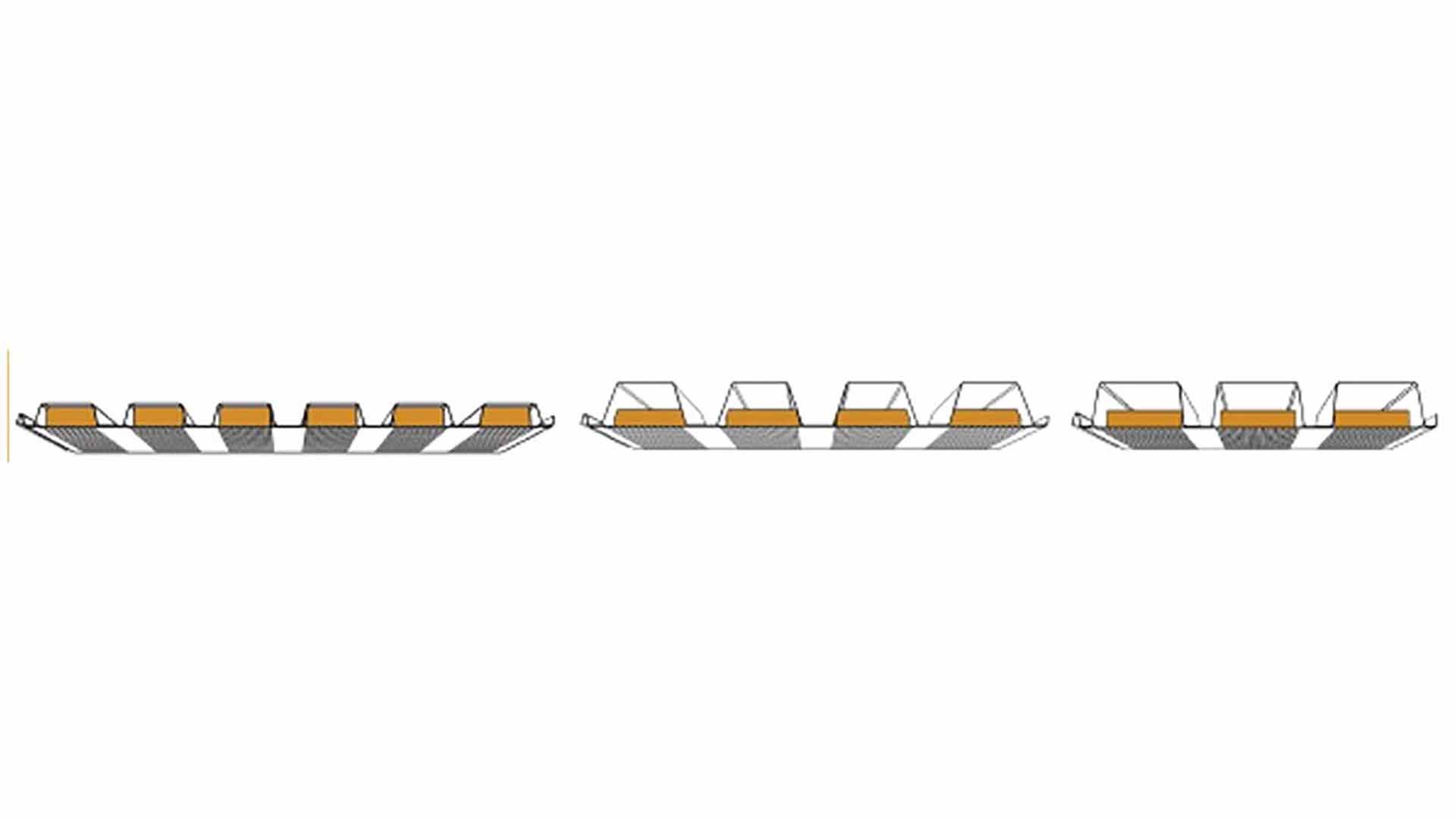

Cellular acoustical metal decking consists of a standard metal deck panel, a perforated flat metal sheet located at the underside of the panel, and sound-absorbing insulation batts. The insulation batts are factory inserted into the void of the metal deck panel.

The perforated flat sheet enables sound to pass through. The sound is then absorbed by the sound-absorbing insulation batts. You will have more noise reduction with a cellular acoustical deck versus a non cellular acoustical metal deck.

Cellular is used when you want more of a finished look. It is when you don’t want to see a corrugated deck when you look up, instead you want to see a flat surface.

Types of Cellular Acoustical Metal Decking

Cellular acoustical metal decking is available in 1 ½” deep and 3” deep fluted roof decks. Available in a galvanized finish. It comes with the option of two different gauges. The metal deck panel is made in either 20, 18, or 16 gauge. The perforated flat sheet is made in 20, 18, or 16 gauge.

It comes in the following gauge options: 20/20, 20/18, 18/20, 18/18, 18/16, 16/18, 16/16. The first number refers to the gauge of the metal deck panel. The second number refers to the gauge of the perforated flat sheet.

1 ½” Deep Type B

The 1 ½” type B cellular acoustical metal deck panels are referred to as HSB-CD AC or PLB-CD AC depending on the sidelap connection.

3” Deep Type N

The 3” type N cellular acoustical metal deck panels are available in two different profiles: types N-24 and HSN3.

Type N-24 cellular acoustical is referred to as N-24-CD AC or PLN-24-CD AC. This is a 2’-0” wide panel with the flutes 8” on center.

Type HSN3 cellular acoustical is referred to as HSN3CD-32 AC or PLN3CD-32 AC. This panel is 2’-8” wide with the flutes 8” on center.

Lead Time

The lead time for cellular acoustical metal decking can take up to 6 months. Lead times can vary largely due to existing backlogs that the factory already has ahead of the order. It is always good to check the current lead time prior to committing to a schedule.

Cellular vs Non-Cellular Acoustical Metal Decking

Both cellular and non-cellular acoustical metal decking offer sound-absorbing capabilities. They both also act as a structural panel offering support to the roof system. However, when comparing both panels, each offers its own set of advantages and disadvantages.

Installation

Cellular acoustical metal decking is heavier and more rigid than non-cellular. It is more difficult to install. It can take over double the time to install resulting in a slower installation that winds up costing more in labor.

Cost

The cost varies based on type, gauge, finish, square-foot quantity, and jobsite location. However, cellular acoustical metal decking is approximately triple the cost of non-cellular acoustical metal decking.

Noise Reduction

Cellular metal decking is more effective at reducing the amount of sound. Having the perforations located on the metal flat sheet along the underside of the panel is more efficient than having the perforations located along the sides of the flutes.

Lead Time

The lead time for cellular acoustical metal deck is double to triple the lead time of non-cellular acoustical metal deck. It can be even more depending on the mill's current workloads.

Appearance

Cellular acoustical metal deck has a flat sheet attached to the bottom of the panel. When it is installed the flat bottom is the finish you see when looking up from inside. The flat finished bottom is a more aesthetically pleasing look vs the corrugated finish you see from the non-cellular acoustical metal deck.

What To Do When You Need Acoustical Metal Deck?

Plan ahead and don’t wait until the last minute because the lead times can be lengthy depending on the different profiles. Anything cellular has an especially long lead time.

You will need to find out what type, gauge(s), finish, number of pieces and lengths so that you can get a quote and approximate lead time.

Western Metal Deck has been dealing with metal deck for 30+ years. We have the experience to do the shop drawings for your project. We can provide you a quote and lead time so you have what you need to bid your project.