How To Bundle A Metal Decking Job & Make a Bundle Location Plan

When you have a metal deck job and are asked to provide a bundling and location plan, you may find it to be overwhelming. A multi-story building can have metal deck that needs to go to many different areas. Metal deck bundles are heavy and typically over 20 feet long. They are not easy to move around, so you want to make sure you have a good bundling and location plan.

A good bundling and location plan is key to having a smooth start to the metal floor deck installation. It can also save money by shaving hours off of the installation, especially since the hourly rate of field work is high.

If you are new to metal deck and not sure where to start on your bundling and location plan, we are here to help. At Western Metal Deck, our metal deck sales team consists of former ironworkers who know first hand the importance of a good bundling and location plan.

We will go over:

- What is a Bundling List

- How to make a bundling list

- How to make a bundle location plan

- Benefits of a Bundling List & Location Plan

What is a Bundling List

A bundling list is a quantity of metal decking sheets that are stacked and banded together to form a bundle.

How To Make A Bundling List

There are some basics that need to be accounted for when creating the bundling list. Creating a bundling list involves more than putting a set amount of sheets into a bundle. Below are some general guidelines to follow, when creating your list.

- First you will need to study the framing plan.

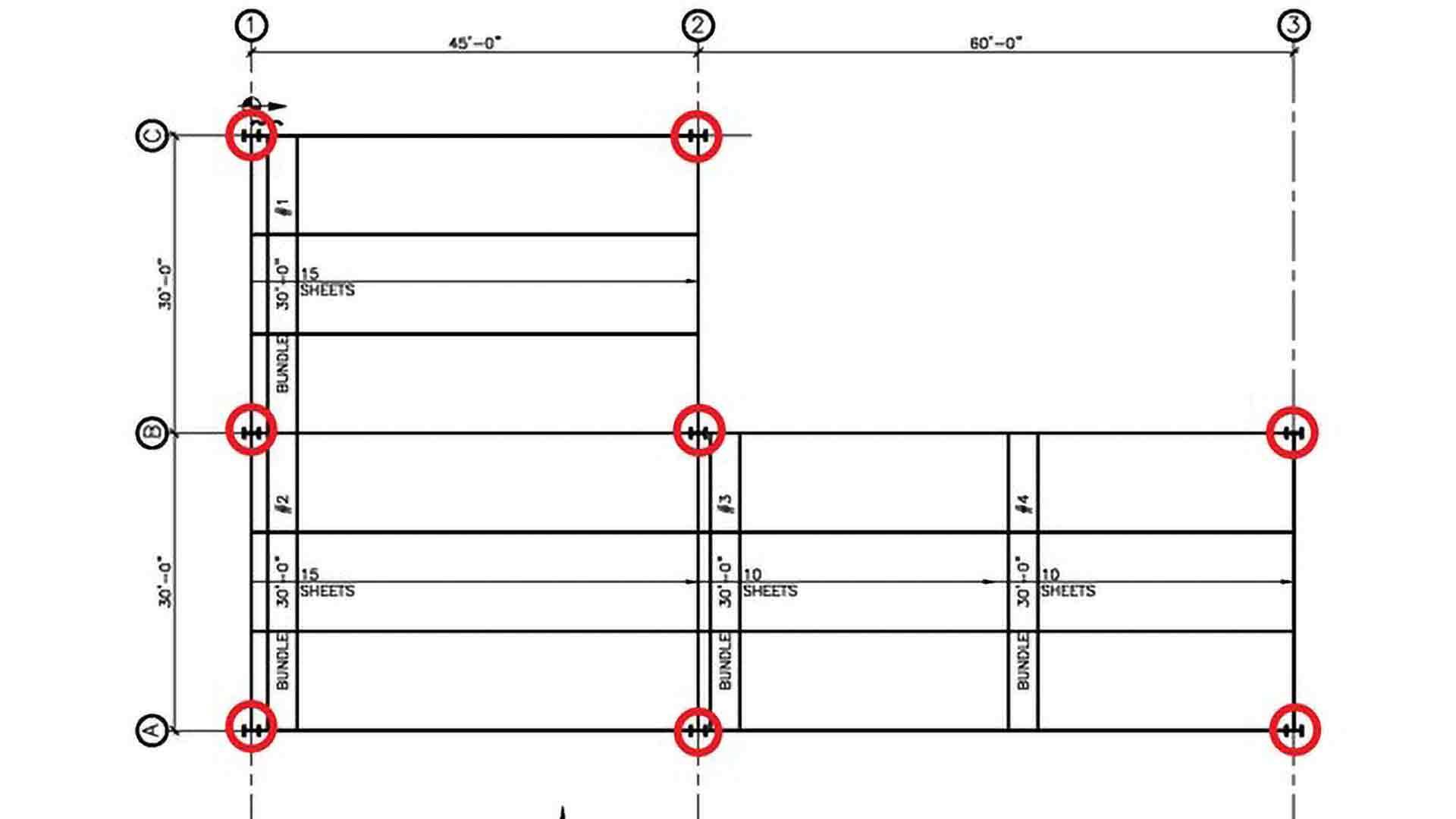

- Determine how many bays are on each level. A bay is the area surrounded by four columns.

Each red circle represents a column

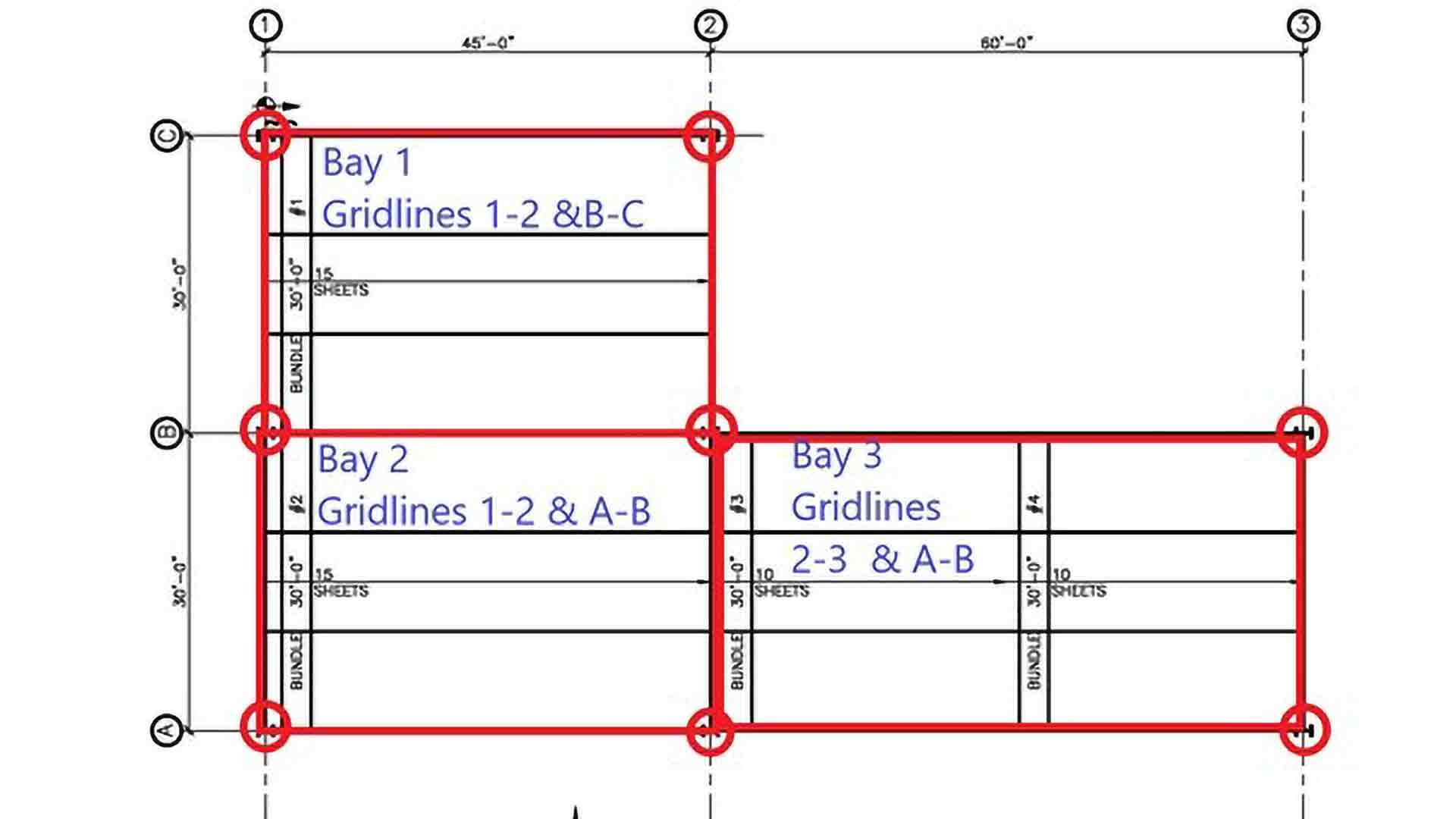

In this instance, there are 3 Bays, as shown below.

- The shop drawings will indicate the number of metal decking sheets that are required for each particular area of the job. They will also show what the length, width and gauge of the sheets are.

- Next step is to create a bundling list for each bay. However, you will need to keep the following in mind:

- The maximum numbers of sheets per bundle is 15 sheets.

- The maximum weight per bundle is 4,000 pounds.

- For an intermediate floor area, the majority of floor decking will be: 3” Deep W3-36 FormLoK™, 2” Deep W2-36 FormLok™, or 1 ½” Deep B-36 FormLok™.

- The sheets are 3’-0” wide and the coverage of a sheet is 3’-0”. There is not any loss of width because the sheets do not lap each other. They have a male side lap on one side and a female side lap on the other side. They lock together without any loss of coverage.

- Determine the width of the bay, to determine number of bundles per bay.

- If this is not possible then split it into two or more bundles.

- In the example above, Bays 1 & 2 are able to be 1 bundle each. Because Bay 3 had more than 15 sheets and was over 4,000’lbs, it was split into 2 bundles.

- If it is possible to cover the entire bay with 15 sheets or less and the gauge permits you to do this while staying under the maximum bundle weight of 4,000 pounds, then it would be good to make 1 bundle for that bay.

- Assign each bundle a number.

Typical 33’ long bundle getting ready to be hoisted up to steel framing.

- Each bundle should have a different number.

- Most metal decking bundles look alike if they are the same panel. It is even difficult for journeyman iron workers to distinguish one bundle from another with just a quick look if they are unmarked.

- Every bundle should have a spray-painted identifying number or letter on both sides of the bundle. Once every bundle is numbered, it is possible to identify each bundle of metal decking on a bundle location plan. Workers will even know where a bundle goes when they see it on the delivery truck just by referring to its number on the bundle location.

How To Make A Bundling Location Plan

Now that you have determined your bundling list for each bay, you are ready to create your bundling location plan.

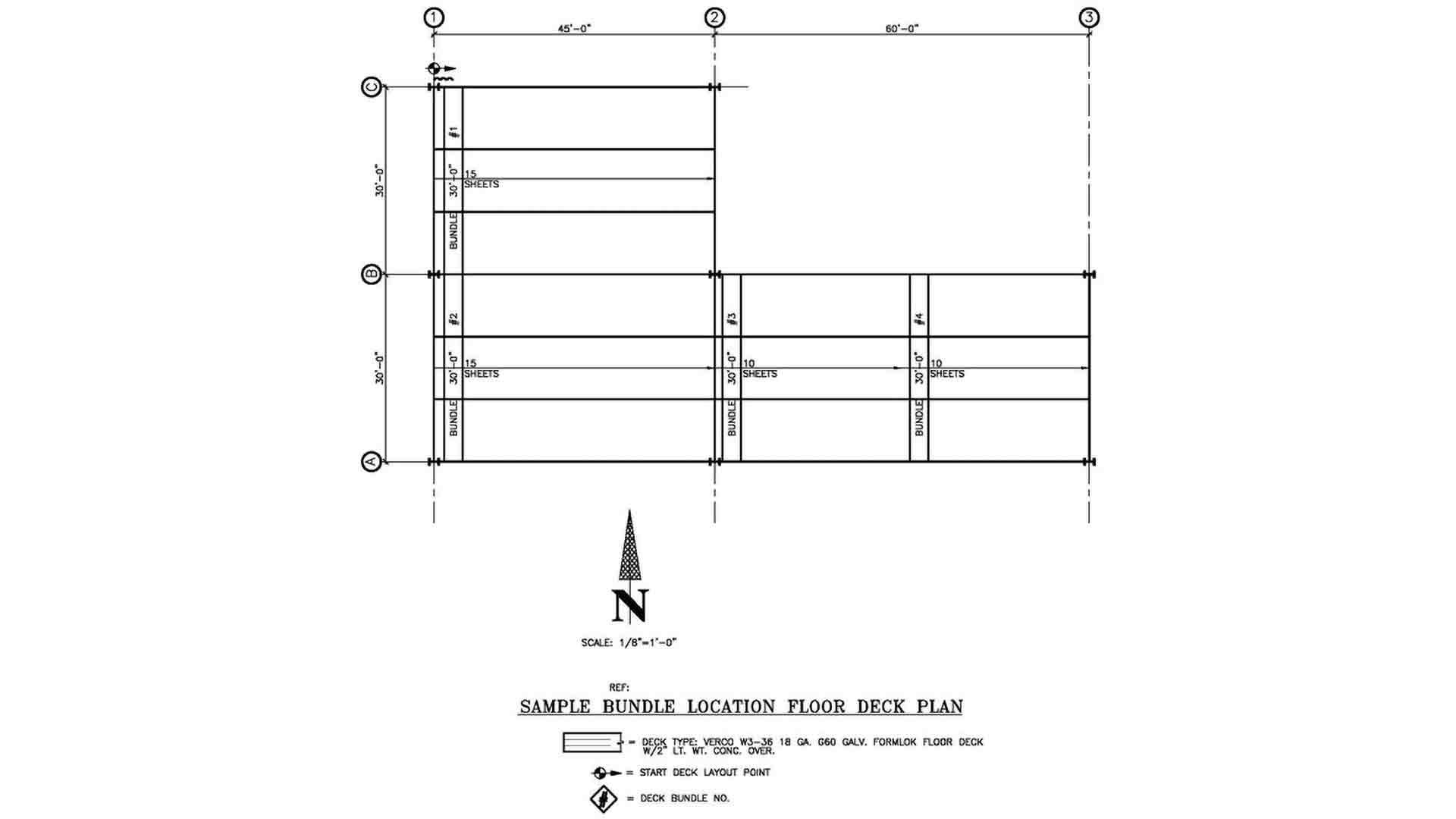

Your bundling location plan should show the following:

- The location of columns and beams for each floor and roof area of the structure. Connection and miscellaneous detailed information is not needed for this location plan.

- Must indicate which direction is North. This is important because normally no one is exactly positive where the erection of the steel frame will begin until it begins. Knowing which direction is North on the bundle location plan makes it much easier to improvise a new plan if things change.

- Every bundle should be drawn on the plan showing its bundle number with arrows indicating in both directions the area that will be covered by the individual sheets in the bundle.

- Where to land the bundle.

- EVERY BUNDLE FOR THE ENTIRE JOB MUST BE SET WITH THE MALE LEG OF THE SHEET FACING THE SAME WAY.

- If one bundle covers the entire bay, land the bundle about a foot away from the perimeter column.

- It is CRITICAL that when the bundle is landed in position the female side of the sheet faces closest to the perimeter column with the male side of the sheet facing closest to the center of the bay. This will allow the sheets to easily lap each other as you spread them during the shakeout phase.

- If it is necessary to split the bay into two bundles then land the first bundle about a foot from the perimeter columns. Land the second bundle at approximately the center of the bay. Once again, it is critical that the male leg be facing the center of the building to match the same direction as the first bundle was facing.

Benefits Of A Bundling List & Location Plan

Be sure to spend time preparing a good, accurate bundling and location plan, it will pay big dividends for your installation’s success. This will end up being one of the biggest factors resulting in your job coming in under budget.

If you don’t have a good bundling and location plan, your job installation will probably struggle and could even cause you to lose money. Once the beginning of a metal decking installation turns bad it is VERY, VERY difficult to get the train upright and back on track. By the time things get straightened out you’re likely to have lost many installation hour.

Ordering Metal Deck

Now that you have your bundling list and bundling location plan you have the final key pieces of information needed to place your metal deck order. Western Metal Deck stocks a large selection of metal deck. We carry different gauges and stock lengths. We can cut to your specific lengths and bundle according to your bundling list.