What are Metal Decking Shop Drawings? Definition and Details

If you are a subcontractor who has been awarded a project with metal decking for the first time, it may surprise you to know that you the subcontractor are responsible for providing the metal decking shop drawings.

If that’s the case you probably have quite a few questions about the metal deck shop drawings process. We understand that the whole metal deck process can feel a bit overwhelming which is why we at Western Metal Deck are here to help. Our team has assisted customers by providing shop drawings and metal decking packages for numerous projects.

We want to help simplify things by laying out exactly what metal decking shop drawings are, what information they provide and what the approval process is for submittals.

What are Metal Decking Shop Drawings?

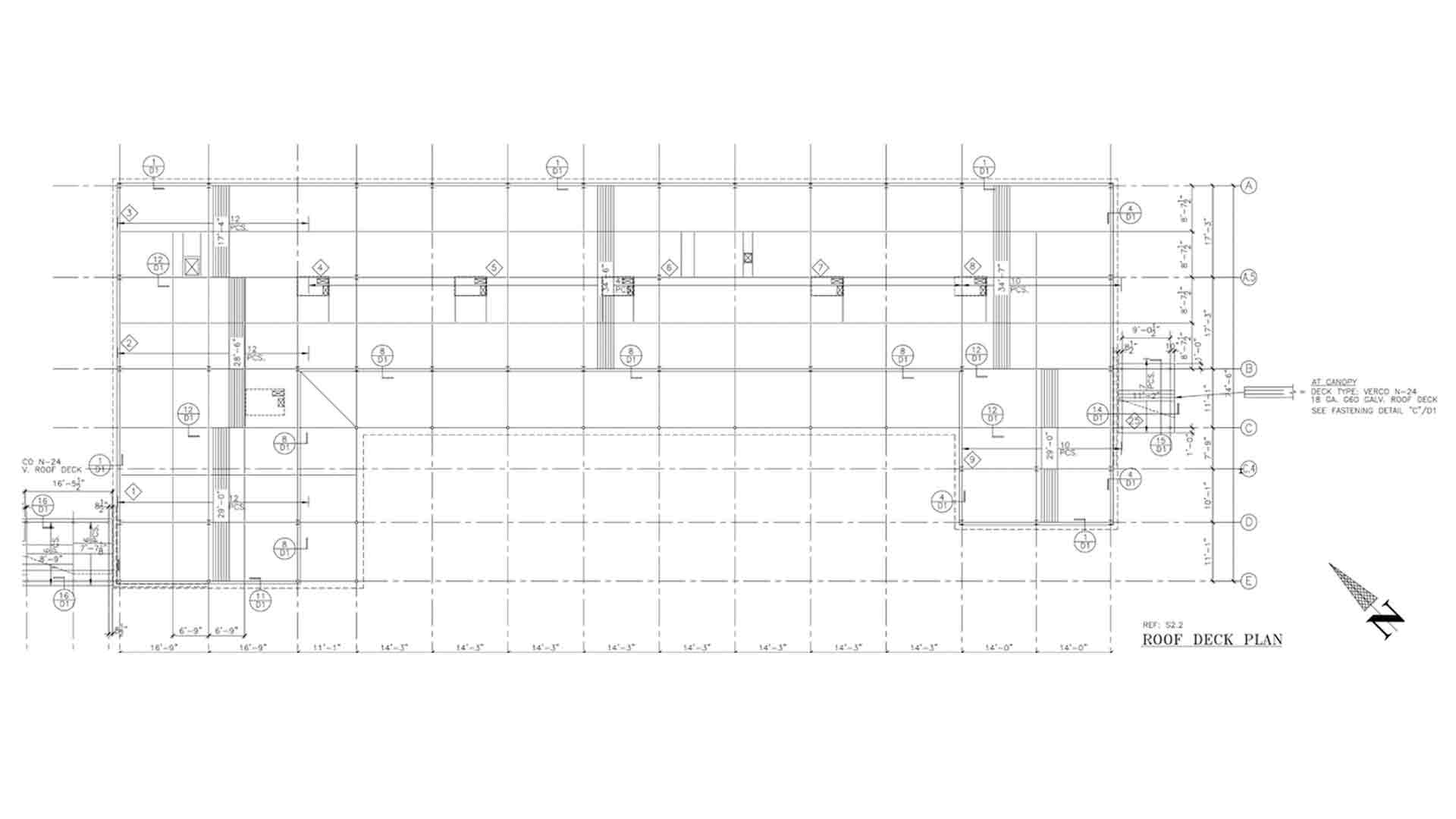

Metal deck shop drawings are linear instructions indicating how to furnish and install metal decking for a project. They provide essential information necessary to complete the metal deck portion of the project.

What Information do Metal Decking Shop Drawings Provide?

Understanding what type of information the metal deck shop drawings provide will help you immensely on your project. From what type of material, to accessories and installation, the metal deck shop drawings are the instructions you need to complete the metal decking portion on your job.

Metal deck

The most obvious piece of information is the specifics for the metal deck. This information will provide you with the necessary criteria needed to place your metal deck order.

The following is an overview of the typical information you will find on the shop drawings:

- The Profile(s) of metal decking used on the project

- The Gauge(s) of thickness of metal decking that will be required at each area of the project.

- The finish of the metal decking

- The length and width (usually in feet and inches) for each piece of metal decking

- The number of metal decking pieces that are in each bundle

- The number that is assigned to each bundle.

Accessories

Accessories for metal decking may not be something you considered, however they are essential in the installation process of the metal deck. You will need to make sure that you have not forgotten to procure the proper accessories or it will slow down your installation.

Below are some of the types of accessory information you will find on the metal deck shop drawings:

- If there are any sheet metal closures at the perimeter of the buildings floors to act as concrete pour stops.

- What size are they: height, width, length and gauge?

- If there are bent plate closures at the perimeter of the building.

- How thick is it and what size (length and height)?

- If there are any gauge closure or bent plate around the openings

- What type is it and what size?

- If there are any shear connector studs welded thru the metal decking into the steel beams.

- Will the metal decking contractor be supplying and installing them.

- What size are they in diameter and length

- How many of the shear connector studs will be installed on each beam and at what spacing.

All of this information should be shown on the shop drawings if shear studs are being supplied and installed by the metal deck contractor.

Installation

Now that you have the metal deck and accessories, you are ready to start the installation process. The metal deck shop drawings will prove to be exceptionally important in this process. It will cover where the metal decking gets placed and how it gets attached. Below is an overview of the installation information that is covered in the metal deck shop drawings:

- The number of spans that should be covered by each piece of metal decking.

- Direction the metal decking should span on all different areas of the project.

- The location that each bundle of metal decking is intended to cover.

- How the metal decking is attached to the interior steel frame of the building and the spacing of the attachments.

- How the sides of the metal decking are attached to each other and at what spacing

- How the metal decking is attached to the perimeter of the building and at what spacing

- Do any of the sheet metal closures or the bent plate closures extend past the outside edge of the perimeter beams and if so by how many inches.

- In addition the shop drawings should clarify which trades scope of work the closures fall into.

- Which openings are designed into the floors and roofs of the building and where they are located. Examples:

- Stair Openings

- Elevator Openings

- Escalator openings

- Shafts & Vents

- Skylights Openings

What is the process for preparing and submitting metal decking shop drawings for approval

To start the shop drawings, the contractor will need architectural and structural design drawings. They will then use the information shown on the design drawings to prepare shop drawings for metal decking.

Submittals

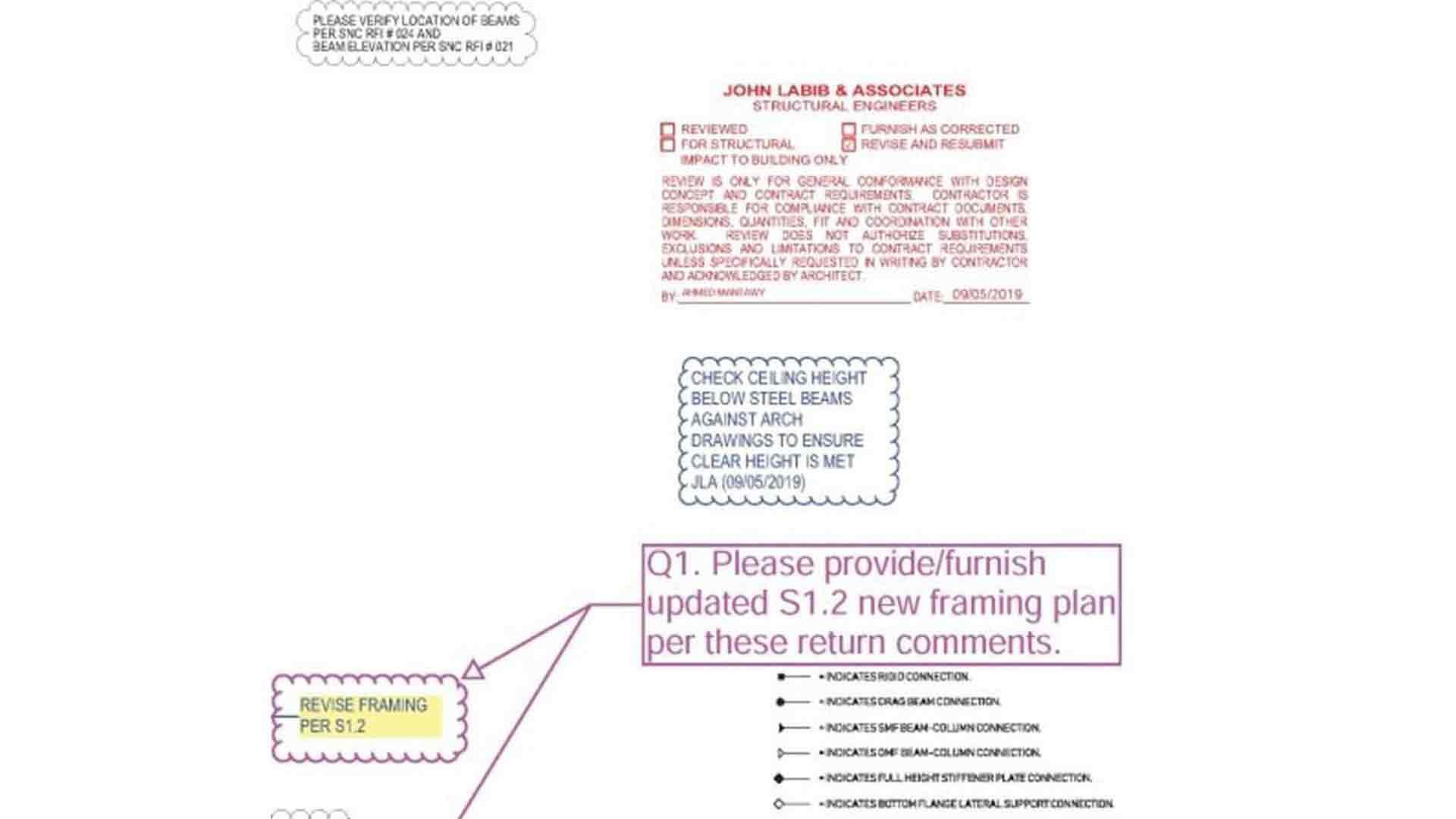

Once completed, the metal decking shop drawings are usually transmitted to the general contractor for approval. The general contractor then submits the shop drawings to the architect and or the structural engineer of record for approval or revisions.

When the structural engineer is done reviewing the shop drawings they will make changes, comments, or approve the drawings. They are then returned to the general contractor who will deliver the shop drawings to the subcontractor.

Sometimes changes are made by the structural engineer and the drawings need to be revised and resubmitted.

Then this process starts all over again. This can sometimes take months to complete the entire process. Due to the fact that the time factor is never a certainty, it is very important to start shop drawings right after receiving a metal deck contract to stay on schedule. Typically, a subcontractor cannot order metal decking until they have approved shop drawings.

Metal Decking material should not be ordered until the shop drawings are stamped approved by the structural engineer of record.

After approval of shop drawings they should also be checked against the approved structural steel erection drawings for any discrepancies or dimensional differences. If everything is correct, it’s time to order metal decking material.

Ordering Metal Decking

To order metal decking, a Bill of Materials must be prepared for the manufacturer. The required schedule should also be shown on the Bills of Materials.The shop drawings should show all of the information needed to prepare a bill of materials including:

- Bundle Number(s)

- Quantity of pieces,

- Type, Gauge, and Finish

- Length of each piece

Start early. Depending on the type of material and the quantity of material involved,the production schedule could take anywhere from a few days to 6 months. For instance, cellular decking will often be the longest of all lead times, typically taking 3 to 6 months.

Do I need Metal Deck Shop Drawings?

The simple answer is yes, shop drawings should always be prepared for a metal decking project regardless of the project's size.

The main benefit for you as the metal decking subcontractor in preparing shop drawings is making the installation run smoothly. This only happens when the installer begins work and knows what material they have, where it belongs on the project, and how to attach it.

The installer also will know what accessories are required and where they belong on the project. This will save you money because mistakes will be minimized.

Western Metal Deck offers metal decking packages. We can provide you a quote to do the shop drawings and furnish the metal deck, edge form, and cell closures you will need.