Metal Deck: Punchlok II® vs Button Punch (Shear Values, Material & Labor Cost)

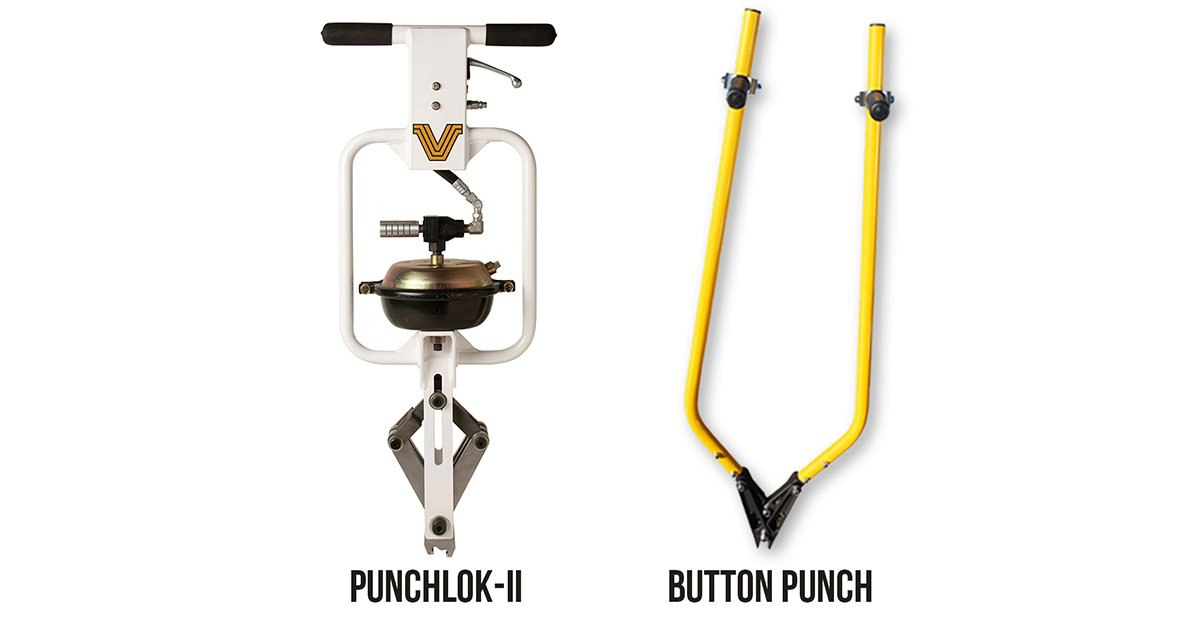

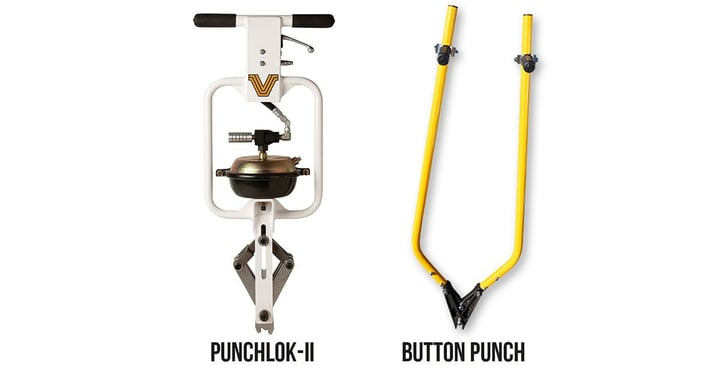

An installation cannot be done correctly without the right tools. When it comes to metal decking, two of the tools most often used are either a Button Punch or a Punchlok II/VSC2 for side lap connection.

In this article, we will do a head to head comparison to determine which of these is best for you to use for your project.

We will discuss how these two types of metal decking compare in these areas:

- Shear Values

- Material Cost

- Labor Cost

Shear Values

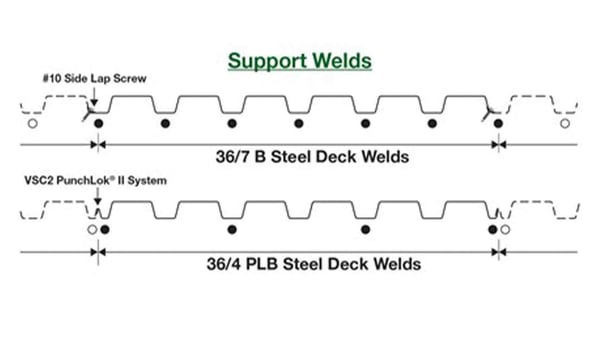

The easiest way to show the differences in the shear values is to break up the shear values for each tool into three categories: low, modest, and high.

Punchlok II

Low Shear Values = Under 500 PLF ( Pounds Per Lineal Ft.)

- Gauge: When the shear values are low you will likely end up using the same gauge for both products.

- Side lap connection: Punchlok II has fewer side lap connections.

- Number Of Welds: Punchlok II eliminates 11,000 welds per 100,000 square feet.

- Gauge: When the shear values are low you will likely end up using the same gauge for both products.

- Side lap connection: Button punch has more side lap connections.

- Number Of Welds: Button punch will have an additional 11,000 welds per 100,000 square feet.

Modest Shear Values = 500 PLF - 1,000 PLF

- Gauge: You can use a lighter gauge of metal deck with Punchlok II and achieve greater shear values when compared to button punch side lap.

- Side lap connection: Punchlok II has fewer side lap connections.

- Number Of Welds: Punchlok II eliminates 11,000 welds per 100,000 square feet.

- Gauge: You will use a heavier gauge of metal deck with button punch and have lesser shear values when compared to Punchlok II/VSC2 side lap connection.

- Side lap connection: Button punch has more side lap connections.

- Number Of Welds: Button punch will have an additional 11,000 welds per 100,000 square feet.

High Shear Values = Greater Than 1,000 PLF

- Gauge: You can use a lighter gauge of metal deck with Punchlok II and achieve greater shear values when compared to button punch side lap.

- Side lap connection: Comparable number of side lap connections.

- Number Of Welds: Punchlok II eliminates 66,000 welds per 100,000 square feet.

- Gauge: You will use a heavier gauge of metal deck with button punch and have lesser shear values when compared to Punchlok II/VSC2 side lap connection.

- Side lap connection: Comparable number of side lap connections.

- Number Of Welds: Button punch will have an additional 66,000 welds per 100,000 square feet.

Button Punch

Low Shear Values = Under 500 PLF ( Pounds Per Lineal Ft. )

Modest Shear Values = 500 PLF - 1,000 PLF

High Shear Values = Greater Than 1,000 PLF

Conclusion

Punchlok II side lap connections allow for the use of lighter gauge steel, less side lap connections, and less welds.

Winner: Punchlok II

Material Cost

The material cost of these panels depends upon the size of the job and the shear values that are required.

Punchlok II

Punchlok material cost 2% to 5% more than button punch side lap decking. On a large job the rental price of the tool is normally included within the price of the steel deck. However, on a small job there is normally a $250 - $500 charge for use of the Punchlok II tool. There is also an upfront cost to purchasing an air compressor and air hoses.

The slightly higher upfront cost are minimal if you have moderate to high shear values. This allows for the use of a lighter gauge of steel. It is common to be able to use a 22 gauge steel with Punchlok II and achiever greater shear values than 20 gauge button punch side lap.

Using a lighter gauge steel could save 10 % to 25 % on your project.

Button Punch

Button punch material cost 2% to 5% less than Punchlok II/VSC2 side lap. Most metal deck installers either own their own button punch tool or can borrow one free of charge with the purchase of the metal decking.

The lower upfront cost are minimal if you have moderate to high shear values. You will need to use a heavier gauge steel with button punch metal decking. It is common to use a 20 gauge steel with a button punch side lap and achiever lesser shear values than 22 gauge Verco or Vulcraft Punchlok II.

Using a heavier gauge steel could cost an additional 10 % to 25 % on your project.

Conclusion

If you have a small job or a job that has low shear values a button punch side lap is likely a better option. However, if you have a larger project with moderate to high shear values than Punchlok II will be significantly cheaper as you can achieve greater shear values with a lesser gauge.

Winner: Tied

- If you have a small job or low shear values = Button Punch

- All other conditions = Punchlok II

Labor Cost

Welding is a significant portion of the labor cost to install metal decking. You will need less welds with the use of Punchlok II. The amount of time it takes to make the side lap connection is similar with both side lap connections.

Punchlok II

The bid rate for a union ironworker including all benefits is $80 to $ 100 per hour. A Punchlok connection is up to five times faster than a top seam weld. In many applications there are 10 percent less welds on a Punchlok II job vs a button punch job. The potential to do 90 percent of the work at 5 times the speed allows for HUGE savings.

In addition, welding is messy. Punchlok II requires no touch-up from either the topside or the bottom side of the deck.

Button Punch

Top seam welds take up to five times longer than a Punchlok II connection. You must use a licensed welder to make a top seam weld. Punchlok II connections can be done by anybody. Having to use a licensed welder that will get less welds per hour will GREATLY increase your labor cost.

Conclusion

Punchlok II is much quicker, allows for less welds, and does not require a licensed welder.

Winner: Punchlok II

Which Tool To Use

The recommended tool to use depends on the specifics of the job.

You should use a Button Punch tool when:

- Shear values are low

- The job is small

You should use a Punchlok II tool when:

- Shear values are modest or high

- The job is large

- Completing the job quickly is a top priority

- You are not a licensed welder

If you still are not sure which tool is best for you, we are here to help. At Western Metal Deck, we offer both types of metal decking. Our sales staff consists of experts that have experience installing and detailing metal decking. We have everything in stock and can even have it delivered within the same day. Delivery is available anywhere within the USA inexpensively on one of our route trucks.

About Paul Rubio

Paul Rubio is the Vice President and one of the owners of Western States Metal Roofing. He has been in the metal roofing industry for 25 years. WSMR is a manufacturer of metal roofing, wall panels, and metal siding. We have colors and finishes that nobody else has with nearly 100 different colors in stock. Our selection of color options and finishes is likely the largest in the industry.