Types Of Metal Deck Closures: Edge Form, Bent Plate, & Cell Closure

When you’re installing metal deck you need to make sure the concrete doesn’t pour out. For this, you’ll need to close off the ends. To do this, you’ll need to use the appropriate type of metal closure.

There are actually a few different types of closures that you can use to close off the ends. Depending on your needs some types will be better suited for your job.

The typical types of metal closures are light gauge edge form, bent plate, and cell closure. At Western Metal Deck we sell metal closure on a daily basis and are asked all the time what the difference is between each type. By the end of this article, you’ll have a good understanding of the different types and be able to choose the right type of metal deck closure for your application.

What Is A Metal Closure?

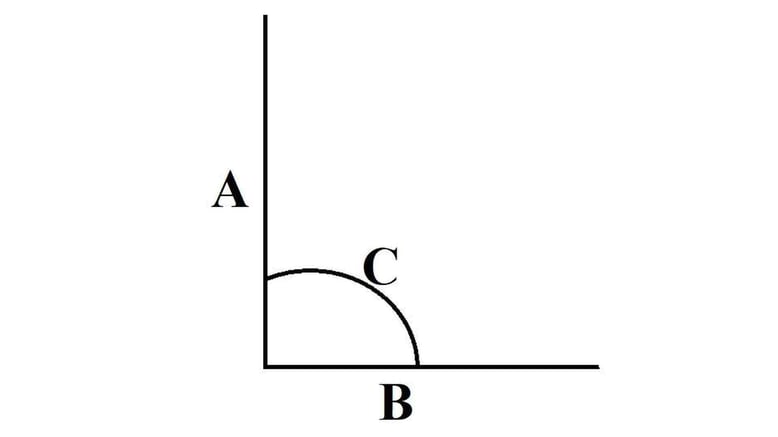

Metal closure, whether it is edge form, bent plate, or cell closure, is a piece of metal that is bent at an angle. Standard metal closure has two different legs (A & B ) which is bent at what is normally a 90-degree angle (c).

Types of Metal Deck Closure: Gauge Metal Edge Form

Gauge metal edge form is used on floor decking to contain the wet concrete during the concrete pour. It keeps the concrete at the edge of the building and/or at the edge of the interior opening for stairwells, elevators, shafts or any other required framed interior openings.

Dimensions

Most gauge edge forms are made to a 90-degree angle shape with a length of 10’-0”.

The height of the edge form leg is typically the same as the thickness of the concrete slab. Meaning if the concrete is 6-inches thick then one leg of the edge form will be 6-inches.

The length of the bottom leg depends on a couple of things:

- If the edge form stops at the outside edge of the perimeter steel beam or,

- If it cantilevers and hangs out beyond the perimeter steel beam.

If the edge form stops at the outside edge of the perimeter beam, then typically the bottom leg of the edge form will be 3” wide. This allows the edge form to have a 3” bottom support leg placed on the outside edge of the beam. The rest of the beam flange is for the metal decking to bear upon since perimeter beams are usually 6” wide or more.

In both cases of cantilevered or non-cantilevered edge form there should be a minimum bearing of 3” on the steel beam flange. The further that the cantilever hangs out past the beam the longer your bottom leg will need to be.

Gauges And Finishes

The majority of gauge edge form is custom made in 10,12,16 or 18 gauge. The finish is typically galvanized G60. The further that the gauge edge form cantilevers past the perimeter beam, the thicker the gauge would need to be. The most popular thickness seems to be 16 gauge.

Stiffening Rib

For additional strength and straightness, the project design may call for a stiffening rib on the top side of the gauge edge form. This consists of a 45-degree break from the top of the edge form down towards the inside of the structure approximately 5/8” to ¾” long.

Types of Metal Deck Closure: Bent Plate Edge Form

Bent plate edge form is made out of steel plate. The thickness of the steel plate ranges from 3/16” thick to about ½” thick. It is used to provide a pour stop form for the concrete floor, similar to what gauge metal edge forms does. Because bent plate edge form is thicker and stronger, it is able to become part of the steel supporting frame.

One main purpose that bent plate edge form serves is to support the outside curtain wall or window wall. Mullions and clips are attached directly to the bent plate edge form. It is strengthened by deformed steel bars that are welded to the bent plate edge form horizontally. They extend into the concrete slab area before the concrete is poured. This procedure gives additional strength to the bent plate edge forms.

Quite often the bent plate edge forms will be shop welded to the perimeter structural steel beams. So when the steel beam is erected the bent plate edge form will be in place.

Types of Metal Deck Closure: Metal Deck Cell Closure

Metal decking cell closures consist of sheet metal angles that are made to fit over the open cell ends of the different types and depths of metal decking. This prevents wet concrete from leaking thru and provides you with a solid closed end.

Cell closures are typically 20 Gauge and come in a galvanized finish. It is available in different sizes and different depths dependent on the metal decking type.

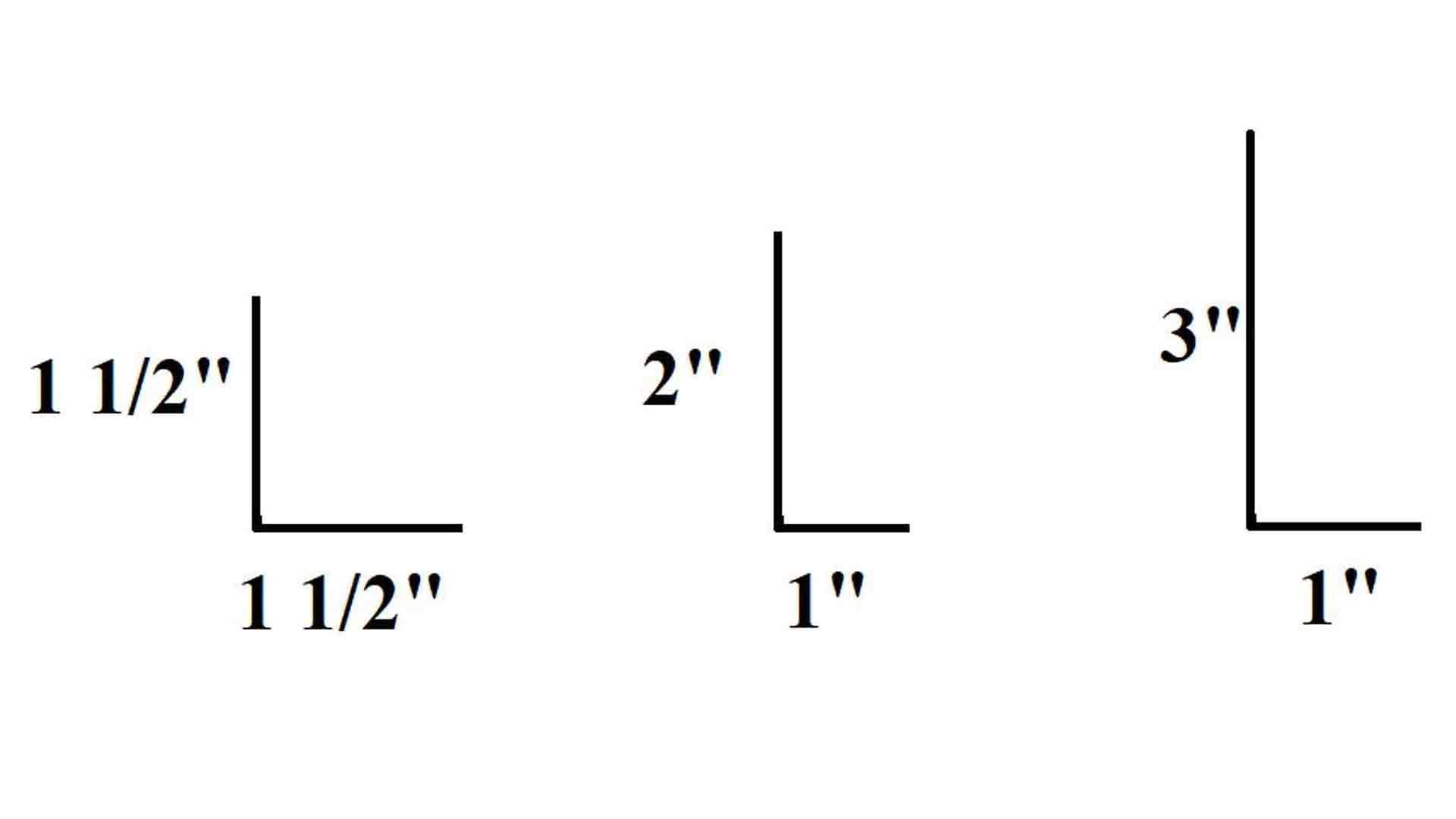

The standard sizes are as follows:

For type 1 ½” B Formlok and HSB-36 Roof deck:

- 1 ½” X 1 ½” X 10’-0” Long strip form or

- 1 ½” X 1 ½” X 4” Long individual cell

For 2” deep type W2 Formlok:

- 2”X 1” X 10’-0” Long strip form or

- 2”X 1” X 7 ½” Long individual cell form

For 3” Deep Decks

Types: W3 Formlok, N-24, N-24 Formlok, HSN3-32 :

- 3’X 1” X 7 ½” Long individual cell or

- 3’X 3” X 10’-0” Long strip form

What To Do If You Need Metal Deck Closure

Metal deck closure is commonly used on floor decking. Chances are if you have metal floor deck then you will need some form of metal deck closure.

If you need cell closure then you will typically be able to purchase this through your metal decking supplier.

Bent plate edge forms are a high-cost item and it is better for them to be shop welded to the associated beams and erected as a unit by the structural steel contractor. Make sure that as a metal decking subcontractor when a bid is prepared that you check to make sure that bent plate edge forms are not in your scope of work.

If you are ordering gauge metal edge form a contractor should check the structural design drawings and determine what gauge is called out, as well as the height of the concrete and length of the leg.

At Western Metal deck we stock cell closure and light gauge metal edge form. We understand the importance of keeping a job stay on schedule, which is why we keep a wide array of metal deck closure to fill most orders.