What Is Form Decking? Types & Uses Of Steel Form Deck

Have you ever heard the term “form deck” and wondered is this just another word for composite floor deck? Does it mean something different?

If you are pouring concrete, then you need something that will support the weight of the concrete. Put simply, a form deck supports the concrete while it cures. There is a bit more that goes into this, but by the time you are done reading this short article you will know all of the basics about form decking.

At Western Metal Deck we’ve been selling metal decking for thirty years. After answering questions about steel form deck and composite floor deck on a daily basis, we decided it was time to write an article to answer all of your questions.

In this article we will cover:

- What Is Form Decking?

- Steel vs. Wood Concrete Forms

- Steel Form Deck vs. Composite Floor Deck

- Uses/Applications

- Types

- Cost

What Is Form Decking?

Form deck is corrugated metal sheeting that’s used as a form for structural concrete. Steel form decking will support the concrete slab during building erection. Form decking is a popular concrete form because it’s economical and it’s a stay in place form. Unlike a wood form, a steel form deck doesn’t have to be removed when the concrete is cured.

Steel Form Deck Versus Wood Forms

Construction projects have concrete that needs to be placed quickly. Typical jobs require thousands of yards of concrete. Normal structural concrete weighs 140 to 150 pounds per cubic foot and that weight adds up quickly. The weight must be held back by a concrete form.

The type of concrete form that will be used on your project will be determined by the size of the pour, thickness of concrete slab, and the volume of concrete that the form needs to maintain. When you are building a multi-story building you need to have a concrete form that’s capable of spanning from beam to beam and support the weight of the concrete. Wood forms aren’t designed for this.

Steel has the ability to support more weight than wood at a cheaper price. Steel form decking is better than a wood form if you have a large area that requires shoring and has to support a lot of weight.

Advantages of steel form decking:

- Fast and easy installation

- Inexpensive

- It can eliminate temporary wood deck shoring

- Saves the time of removing the temporary shoring

- Serves as a work platform when pouring and preparing for concrete

Steel Form Decking vs. Composite Floor Deck

W3 Formlok Composite Floor Deck

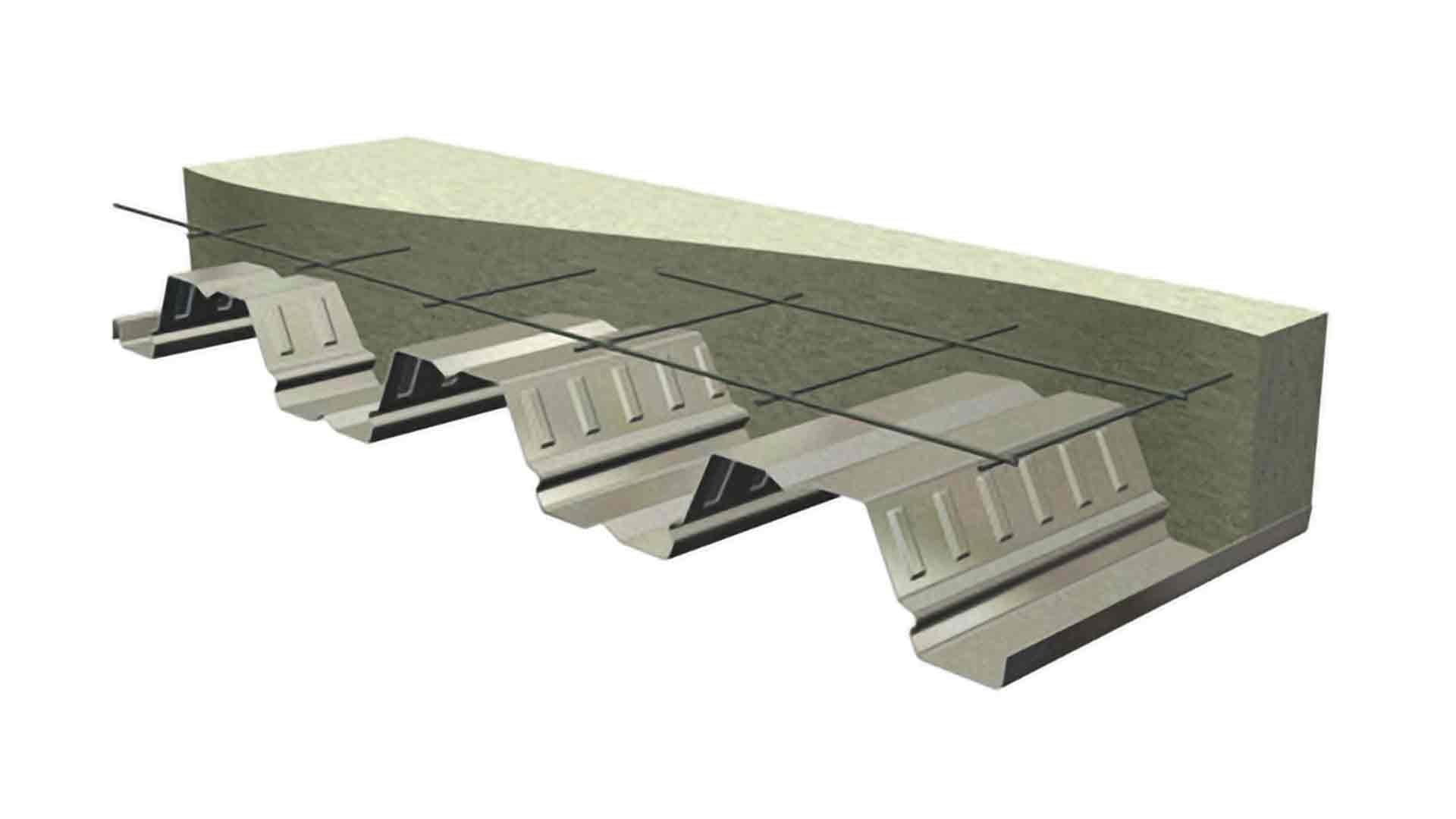

Steel form deck and composite floor deck are both used to support wet concrete and are similar in many ways, but there is one distinctive difference. Steel form decking does not increase the strength of the floor. Composite floor deck will increase the strength of the floor system.

Composite floor decking has embossments in the vertical ribs of the metal decking. The embossments bond with the concrete slab. Once the concrete is cured, the concrete and the metal decking become one item that’s bonded together. They become a composite metal floor deck. Composite metal floor deck systems increase the strength of the floor without adding extra weight.

Steel form decking will simply support the weight of the concrete. It’s a smooth panel and there aren’t any embossments. It will not become bonded to the concrete. Therefore, it does not increase the strength of the floor. It just provides a form for the concrete to be poured on.

Steel form decking is rarely used for long spans or concrete slabs in excess of 6 inches. Composite floor deck is designed for longer spans and can be used for slabs that are 3.5” up to 7.5” deep.

Uses And Applications Of Steel Form Deck

Wet concrete has no strength and it’s heavy. The concrete has to cure so that it will develop the desired strength and durability. By far the most common application of steel form deck is to provide temporary shoring while the wet concrete cures. It’s ideal when a concrete composite is not required.

Steel form decks typically will have spans of 2’ to 5’ and a concrete slab thickness of 3” to 6”. It’s perfect for floors in which the supports are close to each other, multi story buildings, and stairways.

Form deck can also be used as a wall panel or metal siding panel. Quite often you will see Shallow Vercor or Deep Vercor used as partition walls throughout mini storage facilities. The main reason you would use Deep Vercor or Shallow Vercor for a wall system is when your project requires a shear panel.

When you decide to pour concrete on a steel form deck there is an important pitfall that you need to avoid. Form decking cannot have a galvalume or zincalume finish. Concrete and galvalume or zincalume are not compatible because the steel will rust very quickly. Form decking should have a galvanized substrate.

⅞” Corrugated is a product that can be engineered for use as a form decking or designed for architectural applications. However, this product normally has a galvalume or zincalume finish. If you are using this type of steel form decking it must have a galvanized finish. In addition, you should verify it’s been engineered as a form decking and not a metal siding panel.

Types Of Steel Form Deck

Form deck is available in different depths, gauges, and finishes. The availability and options varies from region to region. These are the four most common types.

Shallow Vercor Form Deck

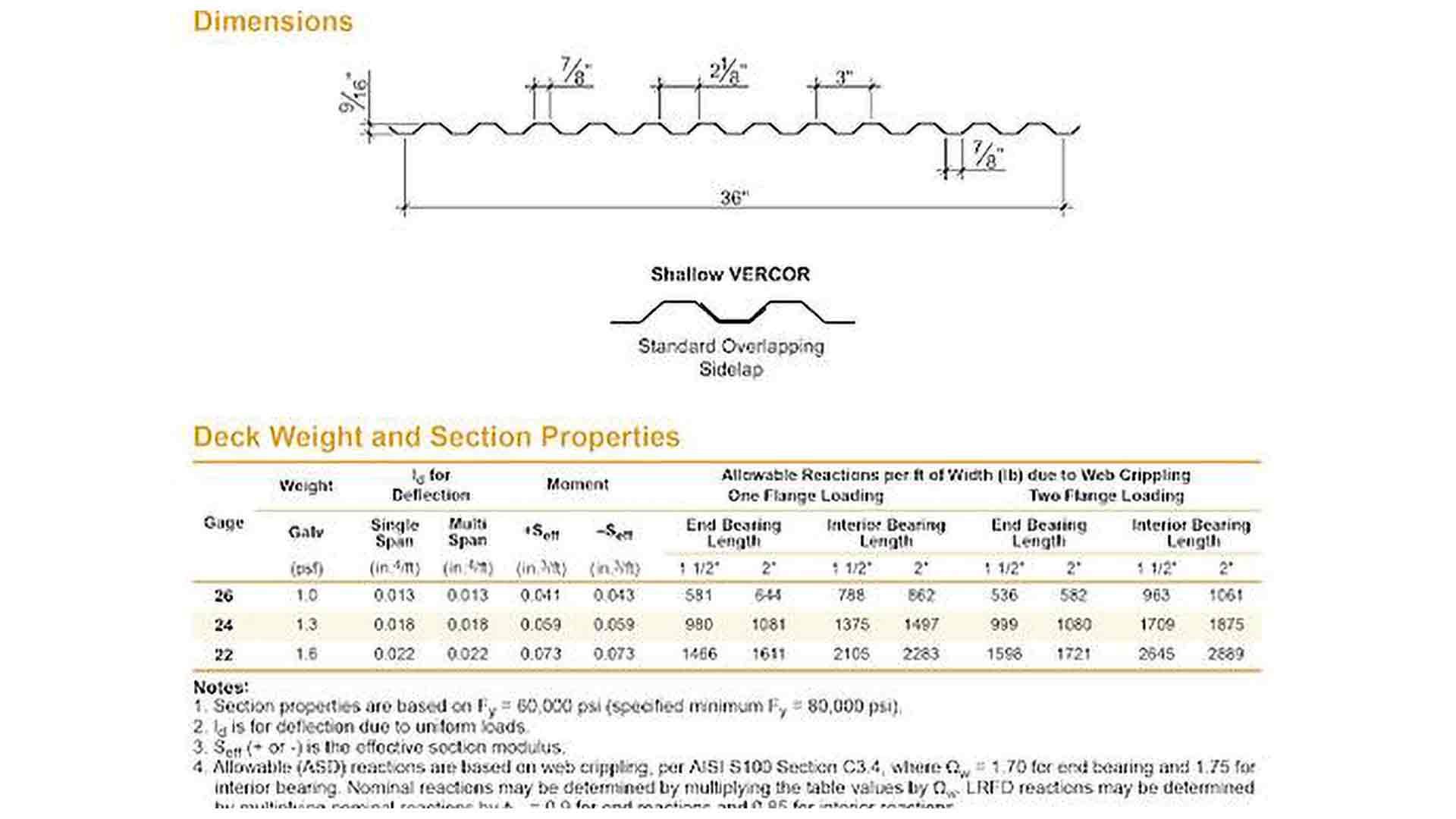

Shallow Vercor is manufactured on the West Coast. It’s the most economical steel form decking and is readily available.

- 9/16” Deep

- Gauge

A maximum of 20 gauge thickness and as light as 26 gauge.

22 gauge material is the most readily available. Heavier and lighter gauges may not be available depending upon your region and job size. - Steel Tensile Strength

High tensile 80KSI steel - Finish

Galvanized G90 - Sheet Lengths

If you have a small job or need the material quickly it’s available in 12’, 16’, and 20’ lengths. If you have 2 to 4 weeks lead time and a larger job, it can be made to whatever sheet lengths that you need.

Shallow Vercor 9/16" Deep Steel Form Deck

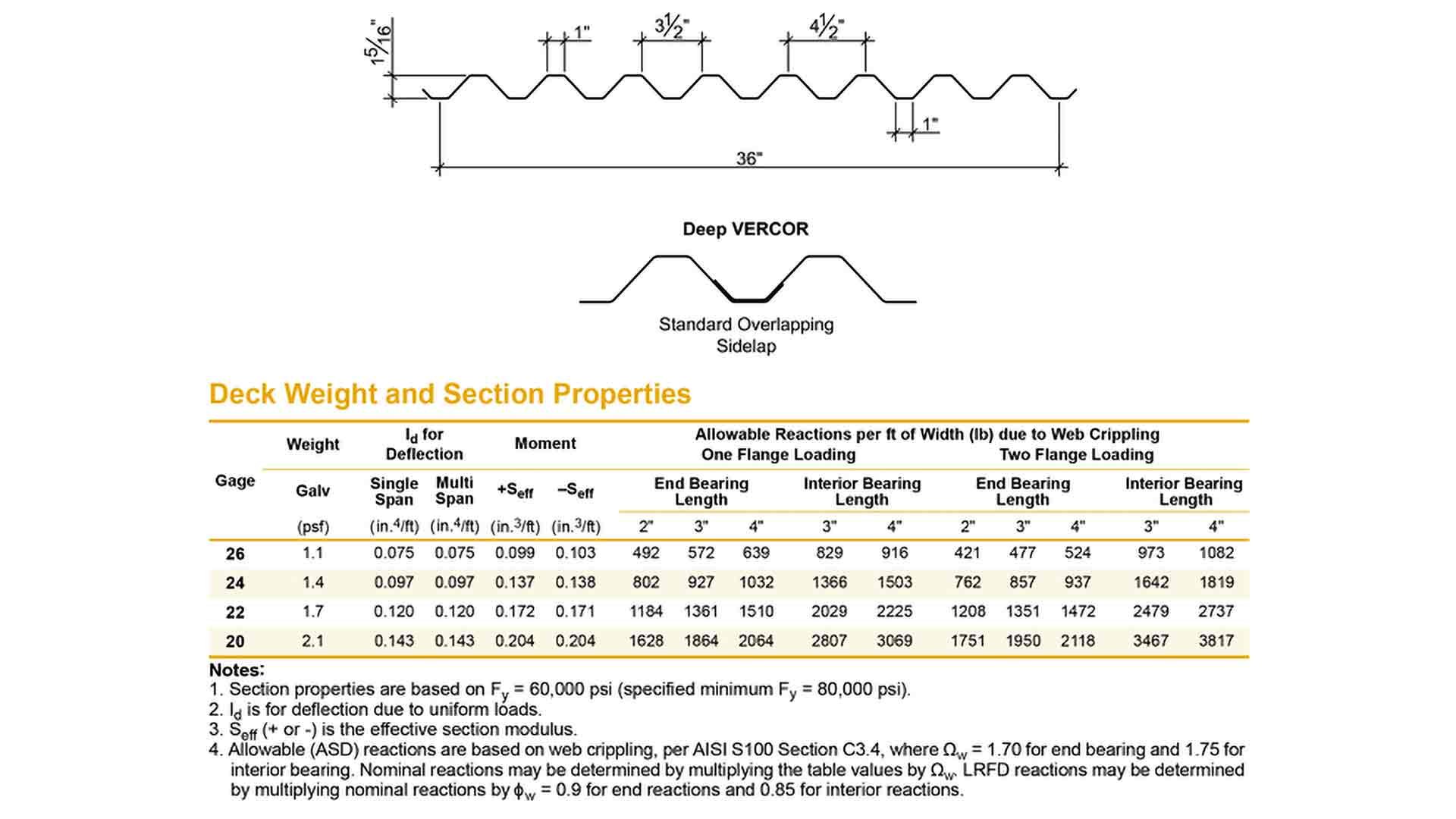

Deep Vercor Form Deck

Deep Vercor is manufactured on the West Coast. It’s a deep and stronger form deck and is usually purchased in a heavier gauge.

- 1 5/16” Deep

- Gauge

A maximum of 20 gauge thickness and as light as 26 gauge.

20 gauge material is the most readily available. Heavier and lighter gauges may not be available depending upon your region and job size.

- Steel Tensile Strength

High tensile 80KSI steel - Finish

Galvanized G90, ASTM A653 - Sheet Lengths

If you have a small job or need the material quickly it’s available in 12’, 16’, 20’ sheet lengths. If you have 2 to 4 weeks lead time and a larger job, it can be made to whatever sheet lengths that you need.

Deep Vercor 1 5/16" Deep Steel Form Deck

Vulcraft 1.0 C, CSV Conform

This steel form deck that is widely used in the middle of the country and on the East Coast.

- 1” Deep

- Gauge

A maximum of 20 gauge thickness and as light as 26 gauge.

20 gauge material is the most readily available. Heavier and lighter gauges may not be available depending upon your region and job size.

- Steel Tensile Strength

High tensile 80KSI steel - Finish

Galvanized G90 - Sheet Lengths

If you have 2 to 4 weeks lead time and a larger job, it can be made to whatever sheet lengths that you need.

Vulcraft ,6 C, CSV Conform

This steel form deck that is widely used in the middle of the country and on the East Coast.

- 9/16” Deep

- Gauge

A maximum of 20 gauge thickness and as light as 26 gauge.

22 gauge material is the most readily available. Heavier and lighter gauges may not be available depending upon your region and job size. - Steel Tensile Strength

High tensile 80KSI steel - Finish

Galvanized G90 - Sheet Lengths

If you have 2 to 4 weeks lead time and a larger job, it can be made to whatever sheet lengths that you need.

If you are welding Verco or Vulcraft form decking at a thickness less than 22 gauge then you should use weld washers.

How Much Does Form Decking Cost?

Form decking will cost $2 to $3 per square foot. The pricing will vary based upon the following factors:

- Gauge

- Size of job

- Location of job

- Fluctuations in the steel market

For a much deeper dive into metal decking costs we recommend:

Get A Quote On Form Deck

Steel form decking is an excellent choice as a concrete form because it’s inexpensive, easy to install, and does not need to be removed. If you think steel form decking is right for you, we invite you to learn more about your options by exploring each type more deeply.

Once you’ve picked the type of steel form deck that’s right for your job, you might find that it’s not an easy product to locate. It’s an extremely niche product and there are only a handful of companies in each region that sell it.

We can save you the time of hunting around the internet as we can ship anywhere within the United States. Let us keep your job on schedule. We have form decking in stock and can have it on your jobsite immediately.

If you have not already purchased your metal decking let us give you a free quote. We have a huge selection of form decking, roof and floor deck, gauges, and sheet lengths.

If you would like to learn more about metal decking, view our blog or YouTube channel.

About Paul Rubio

Paul Rubio is the Vice President and one of the owners of Western States Metal Roofing. He has been in the metal roofing industry for 25 years. WSMR is a manufacturer of metal roofing, wall panels, and metal siding. We have colors and finishes that nobody else has with nearly 100 different colors in stock. Our selection of color options and finishes is likely the largest in the industry.