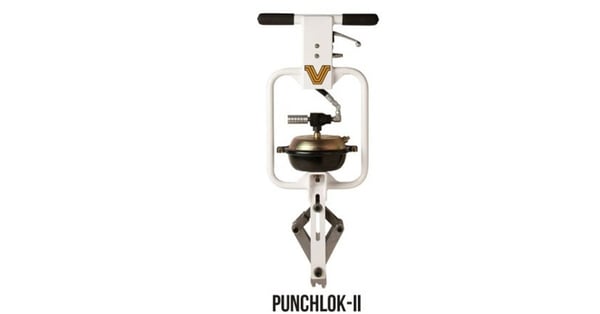

How to Operate the Punchlok II Tool: What Equipment Will I Need?

If this is your first time encountering a job with the Punchlok II tool requirement, you probably have a few questions. You’ve probably already learned where to get the PunchLok II tool, and what the tool used for. But one of the most important questions that you probably have is: how do I operate the PunchLok II tool?

At Western Metal Deck we have been supplying Punchlok metal decking and the Punchlok tools to customers since the Punchlok system was first introduced over 10 years ago. We have consulted with those same customers to get you the information you need to know on how to operate the Punchlok II tool.

We will cover the following to make sure you have all the resources you need to Punchlok II your next job:

- What equipment do you need to operate the Punchlok II tool?

- The Proper Air Compressor Settings

- Required maintenance

- Setting up your work area

- How to operate the PunchLok II Tool

- Safety procedures

What equipment do I need to operate the Punchlok II tool?

In order to make your job go smoothly and save time and money, you will need to make sure you have the required equipment. You’ll need an air compressor and an air hose to properly operate the Punchlok II tool.

What Type of Air Compressor do I need for the Punchlok II tool?

|

|

The most important item you need to operate the Punchlok II tool is an air compressor. The air compressor is what you will use to supply power to the Punchlok II tool. The proper compressor needs to be capable of creating 110(PSI) pounds per square inch.

We recommend Rolair 5.5-HP 9-Gallon Gas Wheelbarrow Air Compressor w/ Honda Engine or the Makita MAC5501G 5.5 HP, because for that size of compressor, they have the best power, storage capacity, length of time to fill the tank of any that we have found at a reasonable cost. As long as your compressor is good for 110 PSI, it will get the job done.

The reason you want an air compressor with 110 PSI capacity is the air tank must be large enough to allow you to work without continually stopping and waiting for the compressor to refill the air tank. If your air tank is too small it could take much longer than it should.

What Type of Air Hose do I need for the Punchlok II tool?

The second most important item you need is an air hose. The right air hose will have a minimum of a ½” inside diameter. The male fitting on the Punchlok II tool is 3/8-inch Diameter, so the air hose needs to be prepared for this size.

The second most important item you need is an air hose. The right air hose will have a minimum of a ½” inside diameter. The male fitting on the Punchlok II tool is 3/8-inch Diameter, so the air hose needs to be prepared for this size.

Depending on the size and power of your compressor you should use a 100-foot-long air hose, the longest air hose you should ever use is 200 feet. If you use an air hose of more than 200 feet,you will get defective punches. This is a result of reduced (PSI) from the air hose being too long.

It is important that the air hose is in good condition without any holes or cracks. If there are any holes or cracks, the hose will leak air and pressure will be lost resulting in defective punches.

The Proper Air Compressor Settings

It is very important that the air pressure be set according to the gauge of the metal decking being used on the job. The chart below will show where to set the air pressure for each different gauge.

These settings represent the PSI needed at the tool. If you set the air compressor to 110 PSI it will correctly crimp metal deck as light as 22 gauge and as heavy as 16 gauge. In addition, if you have a job with multiple gauges you will not have to remember to change your air compressor settings.

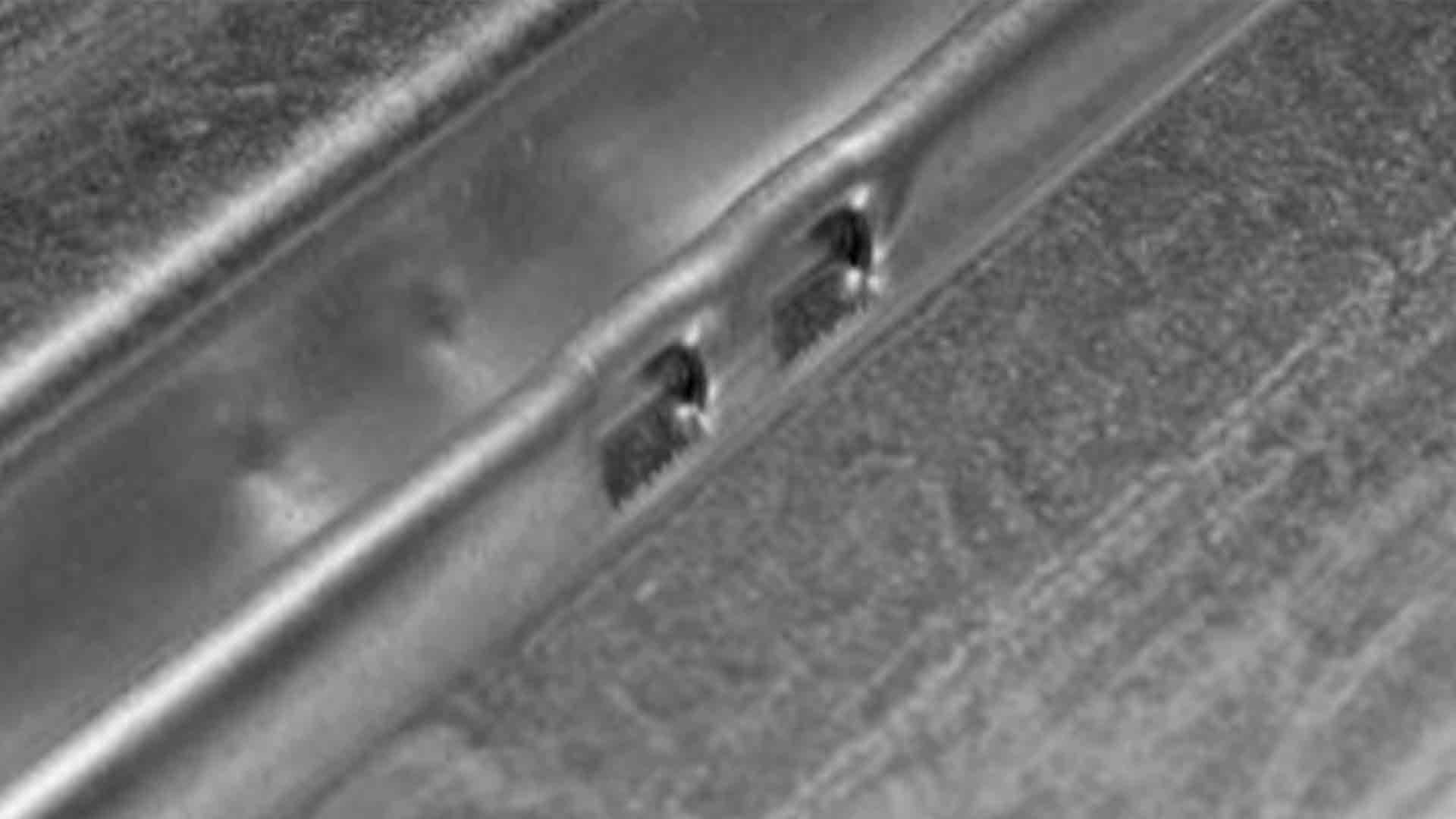

If the pressure is not set correctly according to the gauge, the crimp will go too deep on light gauges or not deep enough on heavier gauges. The inspector can reject the work if the crimp is wrong.

| 22 Gauge | 40 PSI Minimum Pressure |

| 20 Gauge | 50 PSI Minimum Pressure |

| 18 Gauge | 70 PSI Minimum Pressure |

| 16 Gauge | 90 PSI Minimum Pressure |

Required Maintenance Prior to Start Up

Prior to using the Punchlok II tool, you will need to perform maintenance.

An important note: Make sure that the air is disconnected from the tool prior to and while performing maintenance to prevent injuries. Never put your hands near the jaws when the tool is connected to the air hose.

Each day you will need to lubricate all moving parts (see diagram) with 3 in 1 multi-purpose oil or Marvel Mystery Oil. This will prevent the tool from breaking down.

Each day you will need to lubricate all moving parts (see diagram) with 3 in 1 multi-purpose oil or Marvel Mystery Oil. This will prevent the tool from breaking down.

Repeat this procedure every 4 hours of operation.

Breaking down rarely happens, but if the tool does break down and you can’t get it to work, or the jaw breaks, take it back to the supplier. They will switch it for you when one is available.

Setting Up Your Work Area

Before starting a job, it is good to visit the jobsite and plan for what to bring. Access to the work areas is different for each job. You will need to get the Punchlok II tool, air compressor, hose and employees to the working floor or roof that is being punched. To get to the work area you may need a ladder, rope and a forklift, which you need to know before starting a job. In certain situations you may have the luxury of a manlift or stairs, but don’t plan on this.

Place your air compressor in a location that gives you the most access on all sides to your work area. Do a visual inspection of your Verco or Vulcraft Punchlok tool to make sure nothing is loose and that there are no missing parts.

How To Operate the Punchlok II Tool:

Before starting, you’ll need to check the design drawings for the proper Punchlok spacing for your job. Once you have acquired the proper equipment, done necessary maintenance and reviewed the safety procedures, you are ready to start operating the Punchlok II tool.

- Attach one end of the air hose to the Puncklok II tool and the other end to your compressor.

- Start the compressor and wait for the pressure to get to the correct PSI setting. Use the reference chart above to get your PSI setting based on the gauge of the metal decking.

- Hold the tool in the upright position and put the jaws over the side lap. Then pull the trigger. You will hear a clicking sound when it’s done. An acceptable VSC2 should look like:

- Do not use the Punchlok at the overlap of the metal decking. It can break the tool.

- Move forward to the next location and repeat the process.

- Keep going until you have completed the job.

- Make sure to lubricate the tool every 4 hours of production.

- At the end of every day, be sure to drain your tank.

Safety Procedures

Before you start punching make sure that you are equipped with the necessary safety gear. You will need:

- Hard hat

- Safety Glasses

- Ear Protection

- Steel Toe Boots

- Work Clothes

- Work Gloves

- Safety Belt

- Lanyard to tie off when working near the perimeter or near openings.

Inspect the work area to make sure it is safe. Make sure all openings have safety cables around them. Also make sure that the entire perimeter of the building or roof has safety cable around it.

An important note: WHEN YOU ARE USING THE PUNCHLOK II TOOL NEVER WALK BACKWARDS. Always walk forward and watch for any obstacles. It is very important never to rest the tool on top of your boot. When you finish the first area, relocate the compressor and start the procedure all over again for the next area.

KEEP GOING UNTIL YOU HAVE COMPLETED THE JOB.

Finished Using the Punchlok II Tool?

Once you have completed using the Punchlok II tool on your job, you need to return the tool ASAP. There are a limited number of tools available, returning the tool promptly will help in not delaying other jobs.

The Punchlok II tool would have been sent to you in a box with packaging. You must return the tool in the original box and packaging that it came in. If you are shipping the tool back via a carrier, make sure to include $5,000 insurance on the tool. This will protect you in case the tool gets lost in transit. When the tool is received back in the same condition it was sent to you, your $5,000 tool deposit will be issued back.

What you need to get started with your Punchlok II job

Prior to even using the Punchlok II tool you need to make sure you purchase Punchlok II metal deck. This is the only way you will be able to get your hands on a Punchlok II tool. The Punchlok system is a proprietary system, you can only use the Punchlok II tool to connect the side laps of Punchlok II metal deck.

At Western Metal Deck we stock Punchlok II metal roof deck and metal floor deck. We stock it in different gauges, lengths, and finishes. We have the Punchlok II tools available to loan out to customers who have purchased Punchlok II metal deck from us. If you need a quote on the metal deck for your job, contact a sales rep today.

Need more information on Punchlok metal deck? Check out some of the articles below:

What is Punchlok & Where Can I Get a Punchlok Tool?

Punchlok II Metal Decking: A Complete Guide