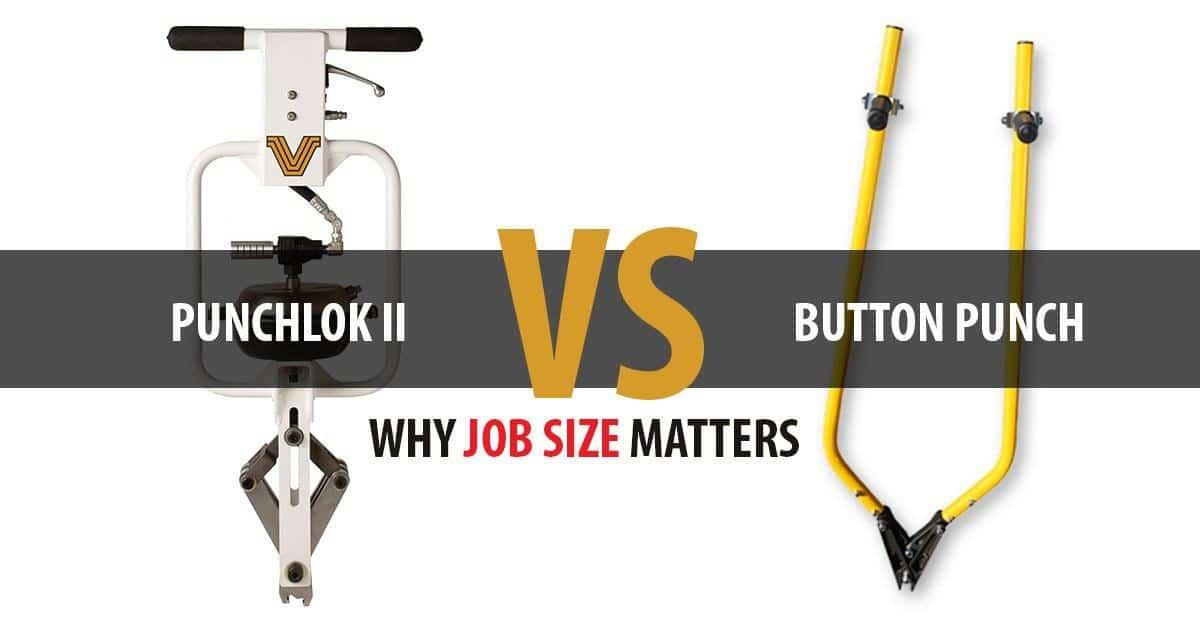

Punchlok II v. Button Punch: Why Job Size Matters

Size matters when deciding which metal deck system is best. It’s important to consider the size of your job when determining which metal deck system is best for you to use.

A small job is generally any project under 100 squares ( 10,000 square feet ), whereas a large job is anything larger than 100 squares.

The two most common tools for metal deck, Punchlok II and Button Punch, have some key differences that make them better suited for certain size projects.

If you need to learn more about Punchlok II and button punch we suggest that you read this article: Punchlok II vs Button Punch (Shear Values, Materials & Labor Cost)

In this article, we will discuss the factors that help determine when it’s best to use Punchlok II or Button Punch including:

Availability

Most jobs have a specific deadline, so any inconveniences that could delay job completion should be avoided. When it comes to tools for metal decking, availability becomes an issue.

Punchlok II

You cannot buy a Punchlok II tool, as they are only available as a loaner tool. Since the popularity of these tools has recently increased significantly, it’s sometimes difficult for the manufacturer to keep up with demand for the tool. As a result, there’s a shortage of Punchlok tools that can result in your project being delayed

This is especially problematic for small jobs. Manufacturers generally try to accommodate your scheduling as best as possible, but larger jobs always have priority over smaller jobs. It is common to wait 1-2 weeks or possibly longer for use of the tool on a small job.

You are also given a very limited amount of time to use the tool. On a small job you are normally allowed 3 days of tool use, with more time given for larger jobs depending on the size. However, the clock starts immediately. It normally takes a day to receive the tool and a day to ship the tool back. In reality this allows for one day of tool usage. Since the tool is bulky, expensive, and time consuming to ship, it is generally preferred to have it be picked up in person instead.

Prior to receiving the Punchlok II, a $5,000 deposit and a signed tool agreement is always required. You will get a full refund back after returning the tool, however, it can take up to a week for the refund to be processed. If the tool is not returned because it is lost or stolen, you will not be refunded.

Normally, the tool is loaned out by the company that sold the job. Large metal decking manufacturers typically will not sell small jobs directly. You will have to purchase the Punchlok material from someone other than the manufacturer that has tool access.

Where To Purchase Punchlok Material And Pickup Punchlok-II Tools

Western Metal Deck in Ontario, CA

Western States Metal Roofing in Phoenix, AZ

Button Punch Side Lap

Button punch tools are readily available. They can either be purchased for $1,395, or loaned to you free of charge with a refundable $1,395 deposit. If you decide to use a loaner tool, you will have more flexibility compared to the Punchlok II with how long you can keep the tool, as there is not a shortage of these tools.

Keep in mind loaner tools are only available if you purchase the metal decking from the company that is loaning out the tool. Prior to purchasing your metal decking ask if they have free loaner tools available.

Time To Complete Job

When you have a metal decking job, you want to be as efficient as possible. It is important that the metal decking system that is specified takes into account the size of the job.

Punchlok II

It takes significantly longer to Punchlok a small job compared to a large job.

With both size jobs, you will need to get an air compressor to the work area, run air hoses and have a power source. The air hoses are hooked up and the air compressor is adjusted to the gauge of the metal decking.

For smaller jobs, setting up and breaking down the work area can take up to two hours between attaching the side lap and unhooking and bringing down all of the equipment. Two hours is a long time when it will take less than thirty minutes to complete the side lap connection.

For larger jobs, the setup and breakdown time is the same, but you will be on the job for days, weeks, or months. The fact, that it took a couple of hours to set up a machine is irrelevant as you will have many hours of side lap attachment.

Regardless of the size of the job, you have to be trained to set up the equipment and use the tool. If you have never done this before, it will take you a minimum of 30 minutes to figure out how to do this correctly.

Button Punch Side Lap

It’s usually faster and more convenient to use a button punch compared to a Punchlok II since the tool is small and easier to transport to the roof. You do not need any equipment or power source. No training is required, just pull the handles and the side lap will get button punched.

Material and Labor Cost

Depending upon your job conditions, it may be possible to use a lighter gauge material. You may also require less welds and side lap connections.

Punchlok II/ VSC2 Sidelap

Cost savings can be substantial using a Punchlok II for a large job, whereas the cost savings are minimal on a small job. Regardless of the job size, a $5,000 deposit is required to use this tool. Although the money is completely refundable, you will be out several thousand dollars if the tool is not returned, as your total deposit will be kept.

Button Punch Side Lap

For a small job, the overall cost of the job will likely be less with a button punch side lap. There is not enough material being used for the heavier gauge to significantly affect the budget.

For a large job, a heavier gauge material may be required depending on the job conditions. You may also have more welds and side lap connections. The overall cost of the job could be significantly higher with a button punch side lap.

The tool itself requires a significantly smaller deposit than the Punchlok II if you choose to rent the tool, at only $1,395 compared to $5,000. However, a button punch side lap is also available for purchase. While it’s a large out of pocket expense, it’s a wise investment to own your tool while also avoiding deposits and wait times.

Changes To Job Specifications

Job delays due to lack of tools often result in an RFI ( Request for Information ) being submitted to change specification on each tool to use. from Punchlok II to button punch side lap.

Punchlok II/ VSC2 Sidelap

It is common to see an RFI to change specification from Punchlok II to button punch side lap to cut down on the wait time for tools. Changing the specifications takes time, as a contractor needs to fill out the paperwork for the RFI and then have it approved by an engineer.

Button Punch Side Lap

There is not a shortage of tools so it’s rare to submit an RFI to change the product specifications to not use a button punch side lap.

Which Tool To Choose

It is important to realize that the size of the job should be one of the biggest factors that influences this decision. Punchlok II was not designed for small jobs, but can potentially save you money on larger jobs.

There are unavoidable issues when using Punchlok II on a small job:

- Shortage of tools which results in job delays

- You CANNOT own a tool

- Lack of cost savings due to the small size of project

- The amount of time it takes to set up an air compressor

If you have a small job of less than 100 squares ( 10,000 Sq. Ft. ), a button punch side lap is recommended, opposed to a Punchlok II, as it would save you lots of time and headaches.

There are potential benefits to using Punchlok II on a large job:

- Cost savings

- Labor savings

- Higher Priority for Tool Usage

If you have a large job greater than 100 squares, using a Punchlok II is recommended as it offers an opportunity for significant savings, opposed to a button punch side lap. In addition, the Punchlok tools are more readily available on larger projects than smaller ones.

Putting A Plan In Place

If you have a metal deck job you need to have a plan for attaching the side lap. You should know prior to purchase of the metal decking whether you will be borrowing or purchasing a button punch.

If you do not install metal decking often then spending $1,395 on a button punch would not make sense. If you plan on borrowing a tool then you must buy the metal decking from someone that has free loaner tools.

If your job requires Punchlok II, a tool that can only be borrowed from a metal decking supplier, then you should have a metal deck schedule and a tool schedule.

At Western Metal Deck, we are knowledgeable on both side lap systems. We have a large inventory of free loaner tools in stock for both systems of metal decking. It’s critical to have the right tools for your job and to have your schedule planned in advance. This way, you can make sure you will have the tool reserved for the days that you will need it.

To get your metal deck project started, reach out to us today.

About Paul Rubio

Paul Rubio is the Vice President and one of the owners of Western States Metal Roofing. He has been in the metal roofing industry for 25 years. WSMR is a manufacturer of metal roofing, wall panels, and metal siding. We have colors and finishes that nobody else has with nearly 100 different colors in stock. Our selection of color options and finishes is likely the largest in the industry.