What is Vented Metal Decking? What Contractors Need to Know.

Vented metal deck is not a typical callout. If you are a contractor and deal with metal deck regularly, then you already know that. But what happens when you suddenly find yourself with a project calling out for vented metal deck? What is vented metal deck? And do I really need it?

At Western Metal Deck, our goal is to help you answer these questions. Our sales team consists of former ironworks who have installed every type of metal deck that you could imagine, including vented metal deck. We have decades of experience of stocking and selling vented and non vented metal deck and are going to help you understand the applications of the lesser seen vented metal deck.

In order to help you understand what vented metal deck is and whether or not you need it we will go over:

- What is Vented Metal Deck?

- A History on Vented Metal Deck

- Vented Metal Roof Deck

- Vented Metal Floor Deck

- Different Types of Metal Deck Venting

- Main Problems with vented metal deck

What is Vented Metal Deck?

Vented metal deck is an added option to metal roof, floor and form deck. The metal deck will have either: vent tabs, rolled form bumps, or drilled holes. This depends on the type of metal deck purchased. Venting should only be used when specified as required based on the materials installed over the deck.

History on Vented Metal Deck

In order to understand what the purpose of vented metal deck is we need to take a look back in history to when vented metal roof deck was necessary. Back in the 1960’s through the 1980’s vented metal deck was used on the majority of steel frame roof decking for commercial and industrial buildings.

It was a necessity to use vented deck due to the type of insulating concrete being used. At that time metal roof deck was covered with either vermiculite or perlite non structural insulating concrete. This concrete weighs only 28 pounds per cubic foot and has a psi of 140 pounds. It was then covered with built up roofing.

Vermiculite and perlite are lightweight minerals and when used as aggregate for the lightweight concrete they create what is known as lightweight insulating concrete. The vermiculite aggregate creates a gas. If the gas is not removed from the roof deck assembly the built up roofing will bubble up and be destroyed by the escaping gas.

The solution to this problem was to vent the gas out with vent tabs or sidelap venting through the bottom of the decking. This allowed the gas to escape without doing any damage to the built up roofing.

In the 1990’s and 2000’s rigid board insulation almost completely replaced insulating concrete. Rigid board insulation does not create any gas. Without the insulation-created gas, there hasn’t been a need to vent the deck to let gas escape.

The vast majority of all roof decking is now non vented which saves contractors and homeowners money.

When Is Vented Metal Roof Deck Still Used?

Metal roof systems will still sometimes require the roof deck to be vented, such as when exposed structural concrete is being poured over it. Venting metal roof deck with exposed structural concrete being poured over it does however create a couple of issues.

When concrete is poured over the vented deck, slurry drips through the vents falling to the floor creating a mess. Measures should be taken to prevent the mess such as laying down plastic sheets. The cost of the plastic and cleanup is added time and money. Which is why nowadays most roof systems have rigid board insulation.

What About Vented Metal Floor Deck?

Floor decking is either covered by wood or in most cases structural concrete. In either case (wood or structural concrete) there is no problem with gas and no need to vent the metal floor deck. The vast majority of all floor decking is non vented.

What are the Different Types of Metal Deck Venting?

There are three different types of vented metal deck. Two are factory types done when the panel is being manufactured. The type of factory venting you need depends on the type of panel you purchase. The third type is an option for hand venting the deck after it has already been manufactured.

1. Factory Vent Tabs

This consists of an elongated slot 1 ½” long in the bottom of the flute at 6” about ¼” wide pushed upwards and staggered.

This consists of an elongated slot 1 ½” long in the bottom of the flute at 6” about ¼” wide pushed upwards and staggered.

The standard applications for this type of vented metal deck are for: HSB-36-B, B-Formlok, N-24, HSN3, W2 & W3.

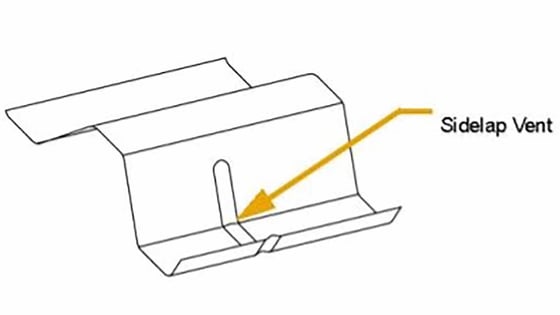

2. Factory Side Lap Vented

A roll formed bump at 10” on center on one side of the sheet when the flat edge of the next sheet is placed on top of the bumped edge. The sheets remain separated apart for gas to escape from.

The standard applications for this type of vented metal deck are for: Deep Vercor & Shallow Vercor

3. Hand Venting

This consists of drilling a ¼” hole at 12” on center staggered in the low of each interior flute.

This can be done in the field by the contractor. If you have purchased your decking from Western Metal Deck, we can do this ahead of time in our shop for a cost of between $.45 to $.50 per square foot.

Main Problem With Vented Metal Deck

Across the metal deck industry the vast majority of companies that stock and sell metal decking do so with non vented material. Non vented material is purchased in large quantities and stocked for quicker availability.

If small quantities of vented material are needed, the material would have to be custom made which could take 3 - 4 weeks. Another option could be hand venting the material after it has already been manufactured. The hand venting costs more, but the time frame is faster helping keep the job on schedule. Hand venting consists of drilling ¼” holes in the low of every rib 12” on center staggered.

Is Vented Metal Decking ever called for when it is not really needed?

YES. This is a very common occurrence. We continually see vented metal deck being designed when it is not needed.

There are a few reasons that this occurs:

-

- Standard spec’s are used which may call for vented floor or roof deck. A call to the contractor, architect, and or structural engineer may be able to clear up the problem and delete the need for vented metal deck. Remember to get the change decision in writing to eliminate confusion later on.

- Venting sounds better than no venting. Most people would choose vented material vs non vented material if they did not have information available to them to help them understand the difference..

- On occasion vented metal floor deck may be called out for on a project because some people believe that the structural concrete will dry quicker with the vented metal deck. Based on our experience, there is no actual evidence to support this.

- Sometimes different companies, government agencies, school districts, and military branches want every upgrade that money can buy regardless if they need it or if it provides any benefits for the money that it costs.

Does my project actually need vented deck?

Since venting is not a huge expense, quite often when it’s called out in spec’s venting will be chosen to play it safe and have peace of mind. Explaining to your customer that venting of the metal deck is not needed will save money and speed up material availability.

Read more about the difference between roof and floor deck: Floor Deck vs. Roof Deck: What's the difference?

Do you need vented metal deck?

We stock metal roof, metal floor, and metal form deck in different gauges and lengths. If you purchase the decking from Western Metal Deck and need your material vented we can hand vent in our shop for an additional cost in a few days or less. If you have more time, we can have your material factory vented within a few weeks.