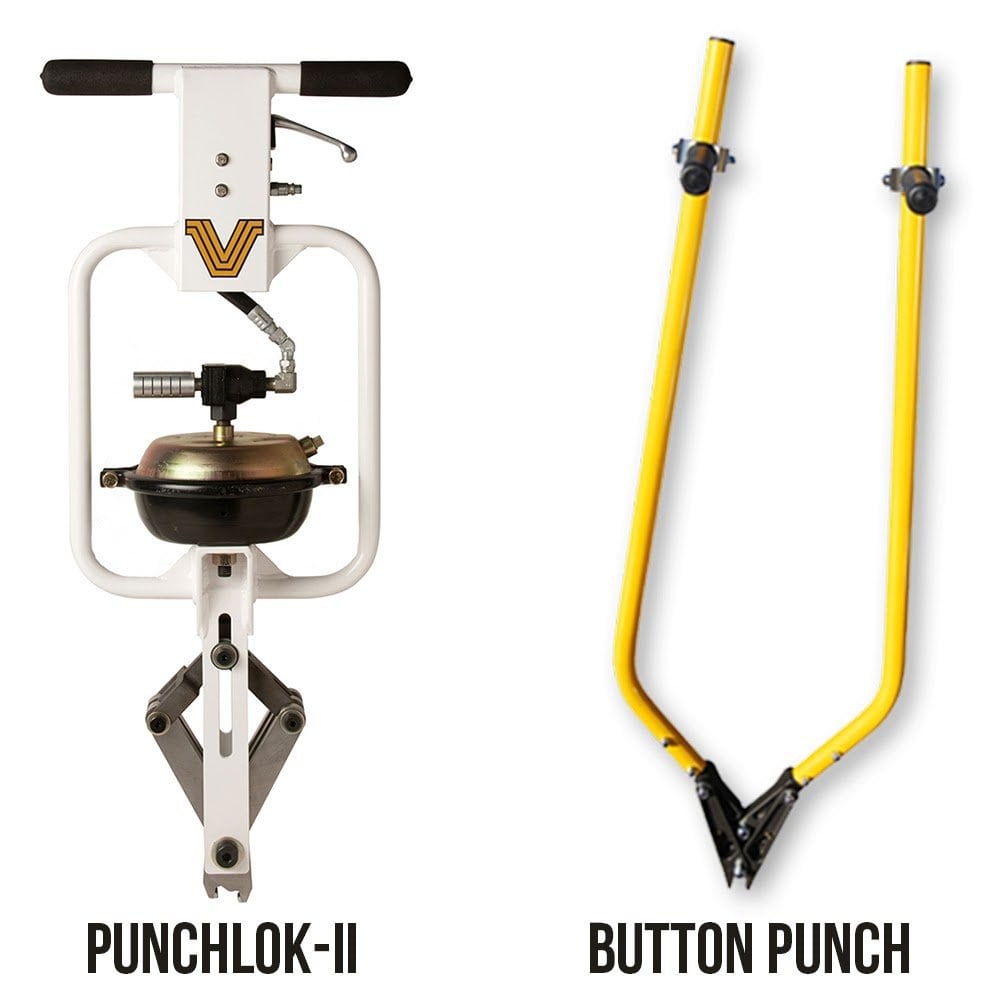

Comparing Side Lap Connection Methods: Punchlok II Vs Button Punch

If you have a metal deck job specified on your plans, you will need a tool to connect the side lap. You have two primary options for side lap connections: button punch or Punchlok II. It’s common to have questions about which sidelap connection is right for you.

We get asked these questions all the time at Western Metal Deck and our goal is to provide you with the best answer.

In previous articles we’ve discussed shear values and labor cost, but in this article we will cover a few of the lesser asked questions and do a head to head comparison. We will pick a clear winner between a button punch and punchlok sidelap connection in each category.

Let’s talk about how these two types of sidelap connections compare in these areas:

- Consistency Of Side Lap Connection

- Weather Tightness

- Versatility

Consistency Of Side Lap Connection

Punchlok II

The Punchlok II tool is designed to create consistent and correct side lap connections. You simply pull the trigger and the machine automatically makes the side lap connection. It will look the same every single time and the seam attachments are easily verified through visual inspection.

Button Punch

This is a hand held tool and as a result there is very little guaranteed consistency. There are a couple of factors that will determine whether the button punch is correct and consistent:

- The gauge of metal deck

- The experience level of tool operator

If you have an inexperienced installer doing button punches on a heavy 16 gauge job for six straight hours, you can expect to have incorrect button punches. They will either crimp too hard and pierce the deck or not hard enough.

Conclusion

Operator error is possible when using a button punch tool. Punchlok tool eliminates the human error component and leaves you with a connection that will be the same every time regardless of jobsite conditions or tool operator.

Winner: Punchlok II

Weather Tightness

Punchlok II

Punchlok II side lap connections are not weather tight. When you look at the connection from underneath you will see light and it will be subject to water leaking.

The penetration that is caused by the Punchlok II tool allows water to leak through the side lap. As a result, the Punchlok II should not be used on a canopy. It would be appropriate for projects with a built up roof.

Button Punch

Metal decking with a button punch side lap is not weather tight without a built up roof system. However, the button punch connection decreases the likelihood of water penetration when compared to the Punchlok tool.

It is common to use button punch side lap for a canopy application.

Conclusion

Neither product is perfect in this regard. Punchlok II will absolutely leak through the side lap and should not be used on a canopy.

Winner: Button Punch

Versatility

Punchlok II is a patented system and can only be used on metal decks that are made by Verco or Vulcraft. The Button punch side lap can be used with nearly any manufacturer's metal decking.

Conclusion

If the metal decking is manufactured by Verco or Vulcraft, then you can use a Punchlok II/VSC2 side lap connection. Otherwise, you cannot use a Punchlok system. Button punch side lap is not dependent upon the metal deck manufacturer

Winner: Button Punch

Which Should I Choose?

On a typical metal deck project the type of panel and sidelap connection is specified by the engineer. What this means is you normally won’t have a choice, the engineer will have specified what to use. Shear values of the product are typically the most important part of the engineering process. Side lap consistency, weather tightness, and versatility are often less important factors.

If you do find yourself having to choose between these two options the decision will come down to what you prioritize most.

If your roof deck needs to be as weather tight as possible, then the button punch side lap connection is the best choice.

If consistency of punches is a concern then a Punchlok II metal deck would be a better solution for you. However, with an experienced installer, it is rare that a side lap is button punched incorrectly.

When Punchlok II is specified on the job, then you have no choice but to use Verco or Vulcraft metal decking. Punchlok II is a patented system and can only be on Punchlok II metal deck which is provided exclusively through Verco/Vulcraft. As mentioned earlier, button punch can be used on any manufacturer's metal decking with a standard interlocking side lap.

Availability of Punchlok Or Button Punch Tools?

Button punch tools can be purchased and will cost you around $1,395. Button Punch tools can also be rented for a fee or loaned for free. Some metal deck suppliers can loan you a tool for free if you purchase the metal decking from them.

A Punchlok II tool cannot be purchased. To rent a Punchlok II tool you will need to have purchased Punchlok metal decking. The tool is loaned out on a job by job basis.

At Western Metal Deck, we stock metal roof deck and floor deck available for same day pick up or delivery. As long as you purchase the metal decking from us, we will loan you the tools for free.

About Paul Rubio

Paul Rubio is the Vice President and one of the owners of Western States Metal Roofing. He has been in the metal roofing industry for 25 years. WSMR is a manufacturer of metal roofing, wall panels, and metal siding. We have colors and finishes that nobody else has with nearly 100 different colors in stock. Our selection of color options and finishes is likely the largest in the industry.