Vented Metal Decking: A Guide To Field Venting

Working in the construction industry you learn pretty early on that once a job gets started, they tend to move quickly. So, when you are told you need to purchase material to keep the job going, you jump on it and try to get it to the jobsite as quickly as possible. The sooner you can get the material to your jobsite the better.

If the material you need to get on order as soon as possible happens to be metal decking, then a metal decking supplier is your best source. They stock various types of metal decking panels. You can get different gauges and lengths on a short 1-2 day lead time.

However, if your metal decking specification happens to have a call out for vented metal decking, you’ll soon find out that vented metal decking isn’t typically stocked.

So what are your options if you need your metal decking vented? Well, you actually have a few options to pick from:

- You can always wait for it to be custom made. However, this option can take weeks. Depending on the size of the job or how quickly the jobsite needs the material, this is usually the worst option.

- Try and get the venting feature excluded or removed from the specification. This can prove to be difficult depending on the requirements of the job and/or the ease of changing a metal decking specification with the engineer or architect.

- Field venting as a substitution for the vent tab requirement. This is the solution we find that works best with our customers. However, this substitution is subject to the approval of the engineer of record, or project architect.

At Western Metal Deck, we are a material supplier of Verco Decking. In order to help facilitate the approval of field venting as a substitution for vent tabs, Verco Decking provided us with letters for field venting their different types of metal decking.

When our customers have a job that needs to be vented, we send them the letter to get the field venting approved, which tends to work 99% of the time. We also offer an option to hand vent the metal decking in-house for an additional fee.

If you are considering field venting metal decking, be advised that the instructions shown below apply to Verco decking and should only be used if you have received approval for field venting.

This article will cover the following:

- The Difference Between Field Venting & Factory Venting?

- What Is Needed To Field Vent Verco Metal Decking

- How To Field Vent Different Types Of Verco Metal Decking

What Is The Difference Between Field Venting & Factory Venting?

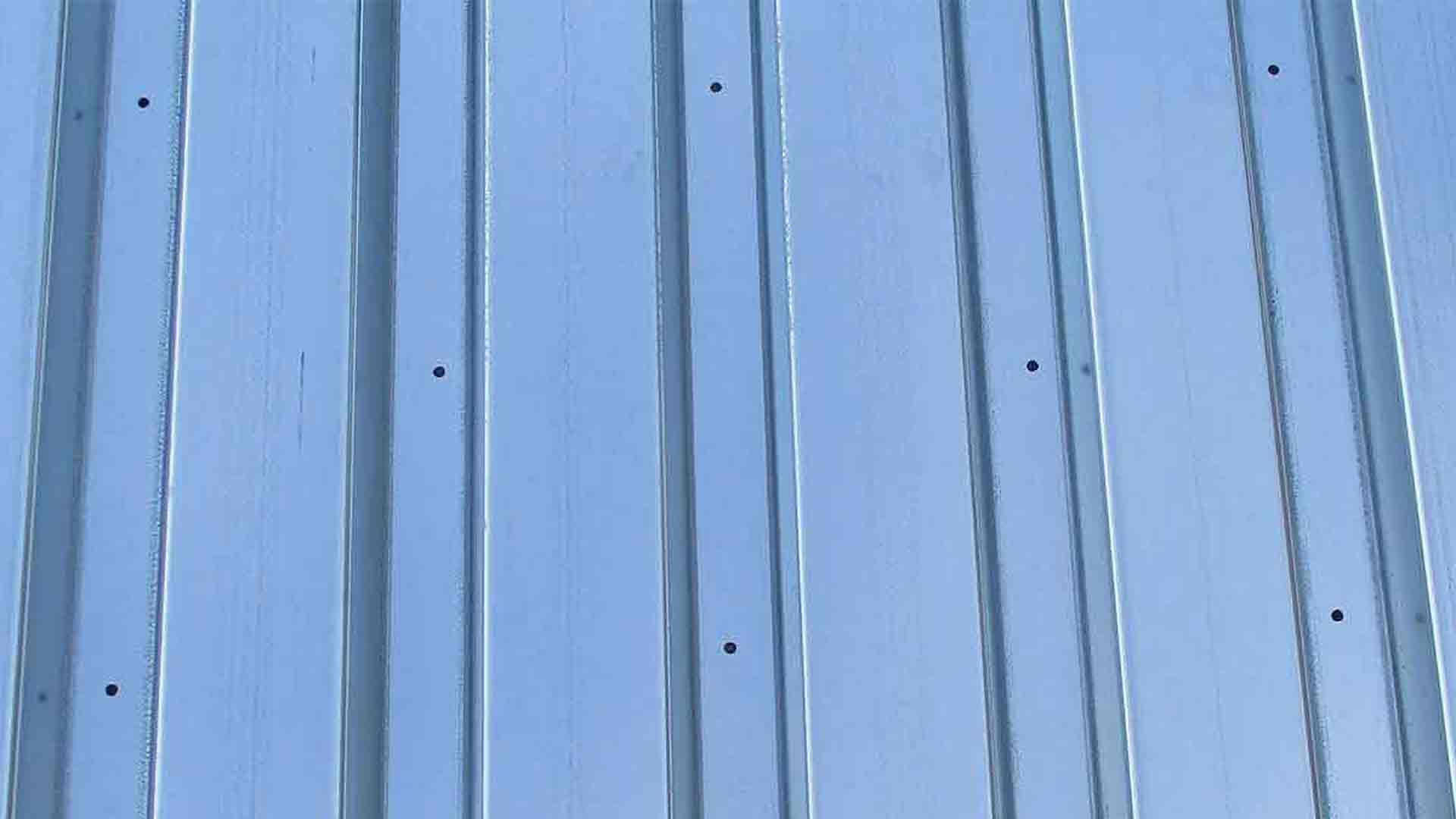

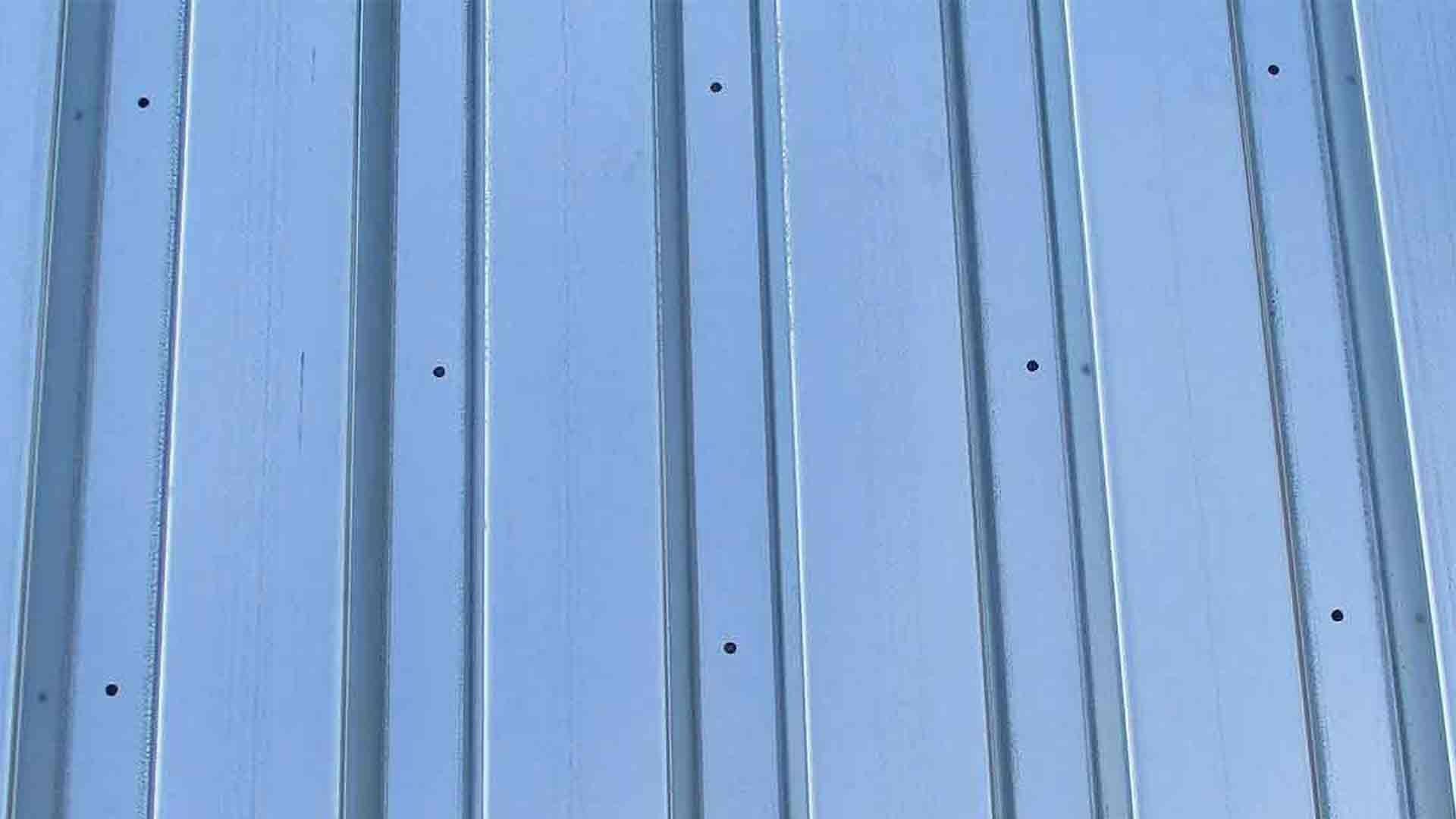

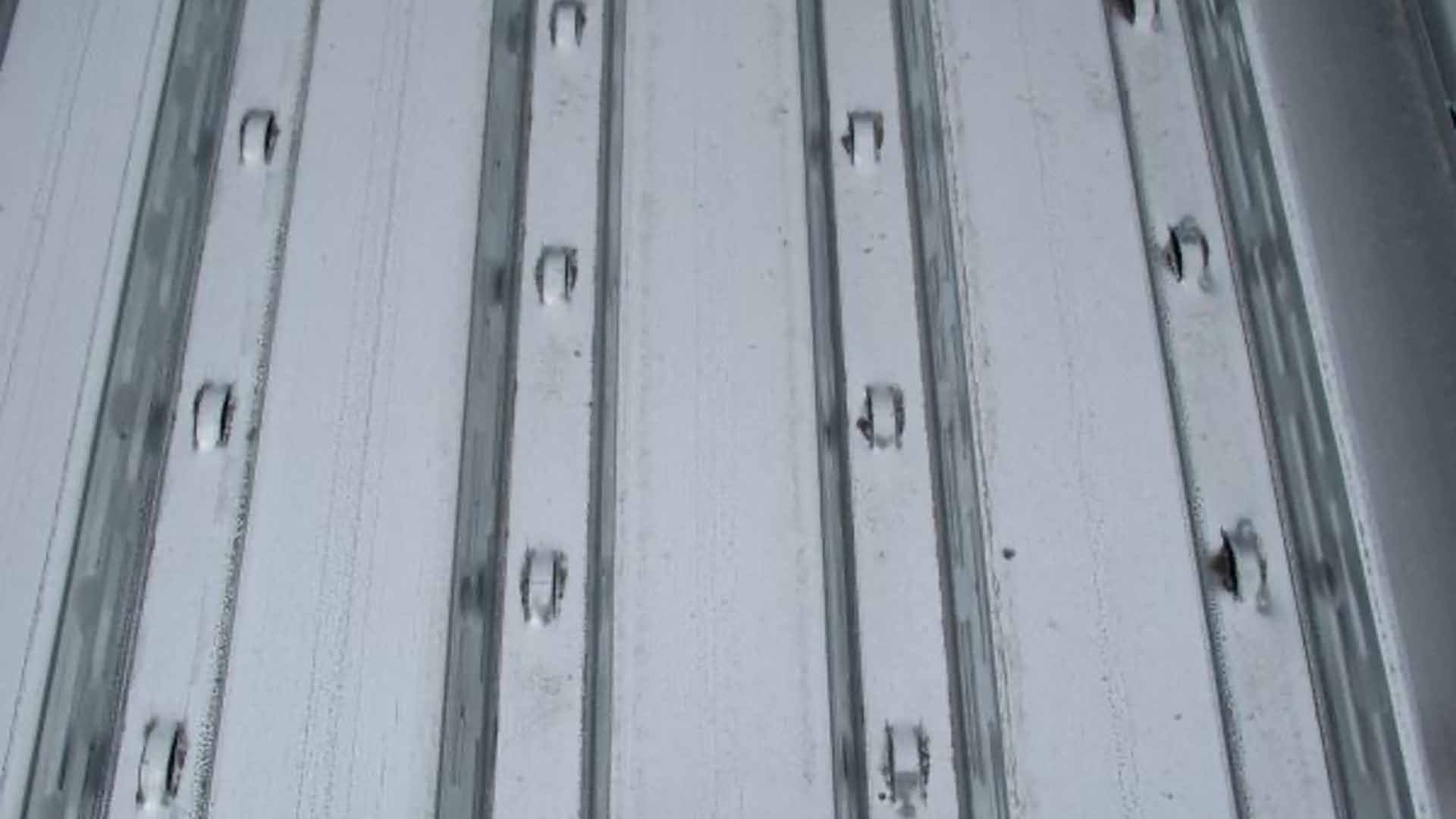

You may be asking yourself what the difference is between a factory vent and a field vent if both are basically a hole in the metal decking. With Verco metal decking the factory venting consists of a vent tab that’s roll formed into the bottom flute of the panel during the manufacturing process. Whereas, a field vent consists of drilling a ¼” hole into the bottom flute of the panel in different patterns depending on the profile type.

|

|

| Factory Venting | Field Venting |

What You Need To Field Vent Verco Metal Decking

Once you get field venting approved you might be considering doing the field venting yourself. If so, then you need to make sure you have everything ready on the jobsite. Luckily, the list of items you need to field vent Verco metal decking is pretty simple and you most likely already have these items in the field.

You will need:

- Verco metal decking

- Drill

- ¼” Drill Bit

- Instructions on where to drill the holes.

How To Field Vent Verco Metal Decking (By Type)

Verco metal decking comes in different profile types. So the manner of field venting is different for each profile. Below are instructions that will teach you how to field vent the different types of Verco metal decking. All directions below are from Verco Decking, Inc. per letters addressed to Western Metal Deck. If you are purchasing metal decking from Western Metal Deck, we can supply you with a copy of the letter to get approval from the engineer of record, to field vent the metal decking.

Field Venting 1.5” Type B

Drilled holes may be installed at the job site. We suggest venting the deck with one row of ¼” diameter holes spaced at approximately 12” on center in the bottom of each interior flute of the deck and in the bottom flange at the female side of the side‐joint (side‐lap). The hole adjacent to the side‐lap should be created (downward) on the female side, to avoid damage to the side‐lap connection. The holes should be evenly staggered from flute to adjacent flute across the panel. Care must be taken to maintain the hole size.

Field Venting Type W2-36 Or W3-36 FormLok

Drilled holes may be installed at the job site. We suggest venting the deck with one row of ¼” diameter holes spaced at approximately 12” on center in the bottom of each interior flute of the deck and in the bottom flange at the female side of the side‐joint (side‐lap). The hole adjacent to the side‐lap should be created (downward) on the female side, to avoid damage to the side‐lap connection. The holes should be evenly staggered from flute to adjacent flute across the panel. Care must be taken to maintain the hole size.

Field Venting 3” Type N Deck

Venting the deck with one row of 1/4" diameter holes spaced at approximately 12” on center in the bottom of each interior flute. The holes should be evenly staggered from flute to adjacent flute across the panel. Care must be taken to maintain the hole size.

Field Venting Type Deep Or Shallow Vercor

Field drilling 1/4" holes in the deck, 3 rows of holes per sheet, holes staggered at 12" on center. If using this method, the deck should be examined after the first several holes are drilled to ensure that there is no crack propagation caused by the drilling.

What To Do If You Need Vented Metal Decking

You want to make sure that if you need vented metal decking that you plan accordingly. If you plan ahead, you will have enough time to have your metal decking custom made and factory vented and may not need to get the field venting approved. However, if you do not have enough time to wait, you want to check with your metal decking supplier to see if they offer a substitution to the factory venting.

As a metal decking supplier, at Western Metal Deck, when our customer tells us they need vented metal decking, we let them know that this isn’t a stock item and offer to send them the letter to get the field venting approved. We also let them know that we can do the field venting in our yard for an additional fee which most customers take us up on, since it can be complicated to do this on a busy jobsite.

Click here to learn about vented metal decking.