What Is Inverted Or Reversed Metal Decking?

On occasion, a metal decking job is designed with inverted or reversed metal decking. When this happens it is important to understand what inverted or reversed metal decking is. Without the proper knowledge, you could easily make mistakes that take huge amounts of money to fix.

The simplest definition for what inverted or reversed metal decking is, would be upside-down metal decking. What it’s called: inverted or reversed, will depend on who the metal decking manufacturer is.

Inverted or reversed metal decking isn’t a typical callout on a construction project. As a former ironworker, I have firsthand experience installing a metal decking job where the reversed metal decking was specified. Follow this guide to learn what you need to know about inverted/reversed metal decking.

This article will cover the following:

- What Is Inverted/Reversed Metal Decking

- Types Of Inverted/Reversed Metal Decking

- Installation Of Inverted/Reversed Metal Decking

What Is Inverted/Reversed Metal Decking?

Inverted/Reversed metal decking is regular metal decking that gets intentionally installed upside down. Installing the metal decking upside down changes the engineering values. As a result, the metal decking is not as strong and can’t span the same distances. However, in certain circumstances the engineer or architect will specify it this way to either create a stronger concrete slab or for aesthetic purposes.

Types Of Inverted/Reversed Metal Decking

Metal decking is available as roof, floor, and form deck in different profiles. When it comes to inverted/reversed metal decking there are a few profiles that are more popular. There are also a few that are uncommon due to the fact that you gain nothing by flipping the sheet over and installing it upside down.

Below we will go through the different types of inverted/reversed metal decking.

Inverted/Reversed Metal Roof Decking

Inverted/reversed metal roof decking is sometimes used as the roofing on commercial loading dock roofs and trash area roofs to protect dumpster rainwater runoff.

Types 1 5/16” Deep Vercor and 9/16” Shallow Vercor are very popular choices of metal decking for these applications. These types of decking already come with a nestable sidelap and when installed in the inverted position the sidelaps end up on the high side of the panel.

Types 1 5/16” Deep Vercor and 9/16” Shallow Vercor are very popular choices of metal decking for these applications. These types of decking already come with a nestable sidelap and when installed in the inverted position the sidelaps end up on the high side of the panel.

Type B deck, with a nestable sidelap, is another type that can be specified for canopies or trash covers. When installed upside down, the nestable sidelap ends up on the top side of the sheets. It’s important to note that this is a special order item which costs more and has a longer lead time.

When the nestable sidelap is on the high side of the sheet it reduces the amount of leakage through the panel. The leakage can be further reduced by calking the sidelap and/or by double side lapping the sheet and calking the sidelaps. The sidelaps are attached using stitch screws.

Water leakage will still occur, however, quite often for loading dock canopies and trash area covers, the side and front of the structures are open to the weather. As a result, a minor amount of leakage is not usually a problem.

These types of roof deck panels should not be used as roofing on a building where the objective is to keep out 100% of the rainwater. A built-up roofing system over the metal decking would be required to keep out 100% of rainwater.

Inverted/Reversed Metal Floor Decking

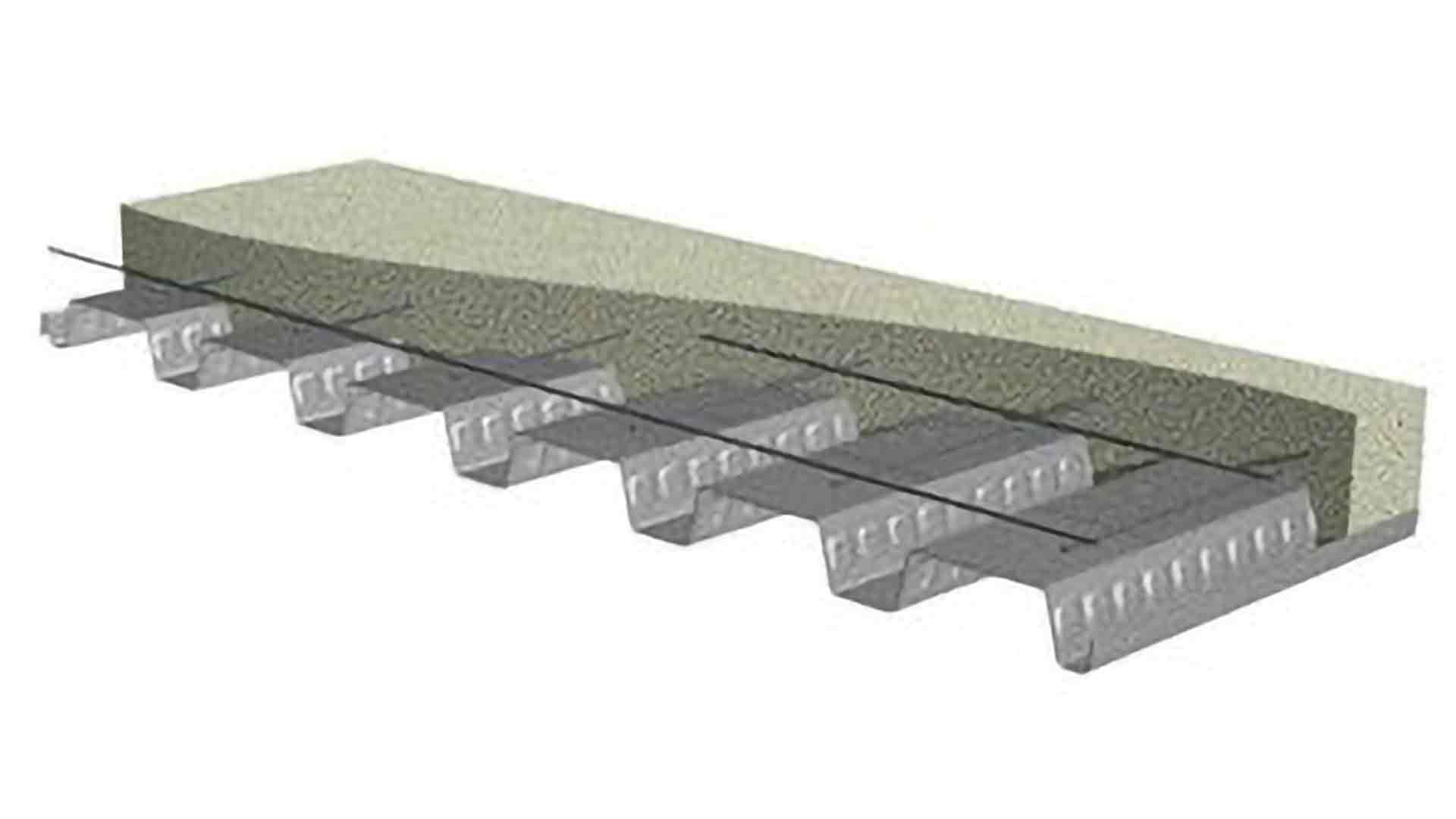

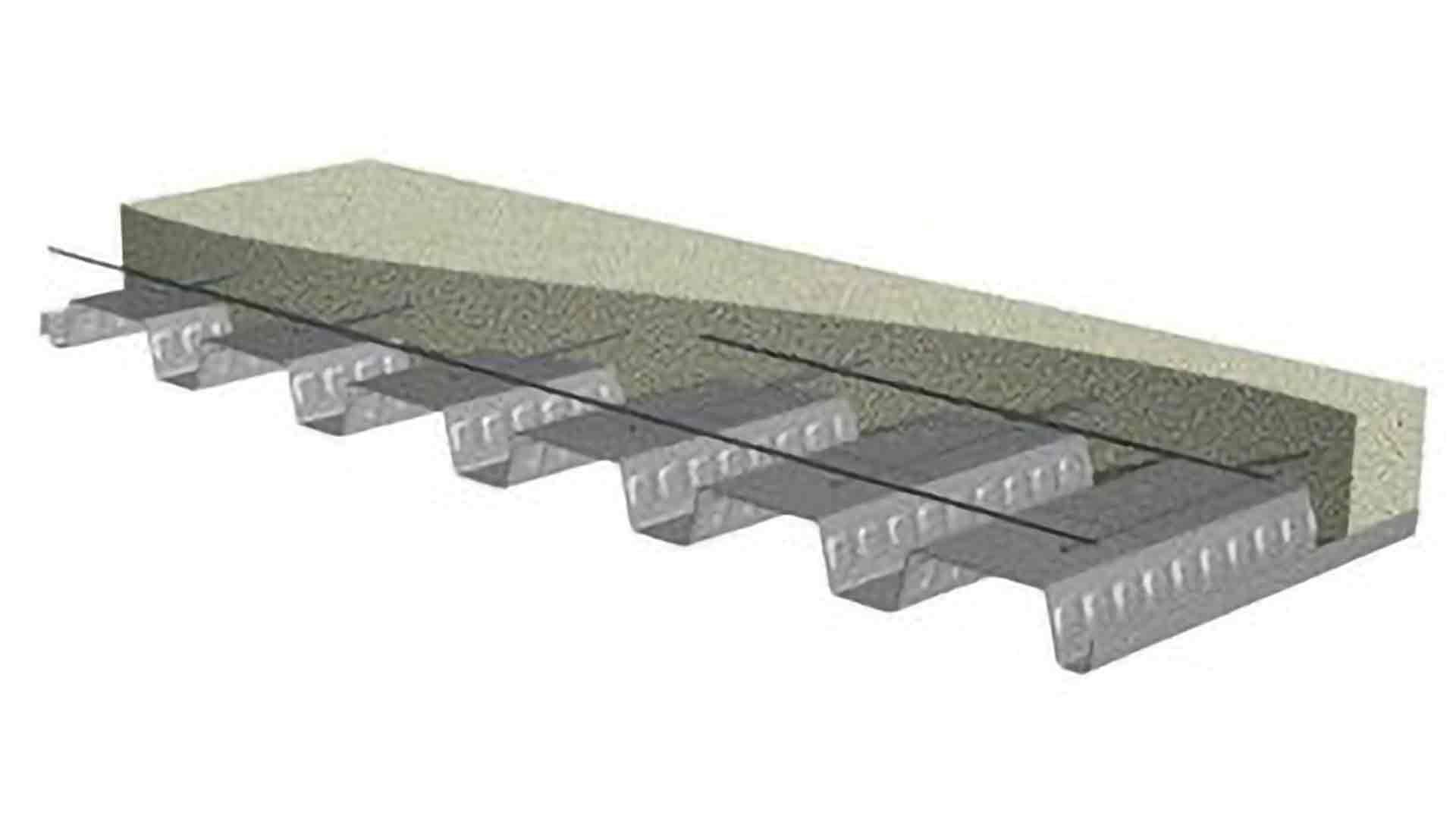

Inverted/reversed metal floor decking is sometimes specified when the engineer needs to create a stronger concrete slab when using composite types 1 ½” B deck or 3” N deck.

Composite B deck with a stitch screw sidelap happens to be the most popular inverted/reversed metal decking option. Engineers will sometimes specify it this way because they need to create a stronger slab. You would normally be able to create a stronger slab by using a deeper panel such as W2-36 Formlok (a 2-inch deep panel) or W3-36 Formlok (a 3-inch deep panel). However, in some instances where the engineer has to save space, they need to use a shallower panel such as 1.5” deep type B deck.

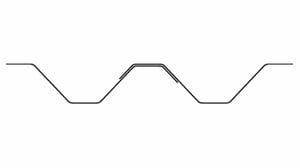

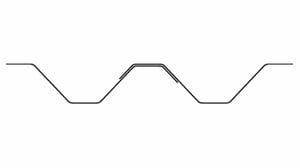

| Standard B-36 FormLok - In the normal position the large rib is facing up towards the sky, so when the concrete is poured the small rib is filled with concrete. |  |

| BR-36 FormLok (Inverted/Reversed) - One way the engineer can create a stronger slab is to specify the panel inverted or reversed. By installing the metal decking upside down more concrete is required to fill the metal decking flutes, thus creating a stronger concrete slab. |

|

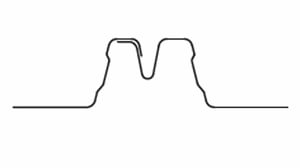

Composite N deck isn’t specified as often, because 3” deep W3-36 Formlok is much more commonly used when the concrete slab requirements require the panel to be 3” deep. W3-36 Formlok is more readily available and can hold more concrete when installed right side up.

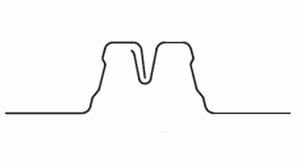

Types 2” Deep W2-36 Formlok and 3” Deep W3-36 Formlok aren’t typically specified to be reversed since nothing is gained by installing the panel upside down. Both sides of the panel can hold the same amount of concrete, however, flipping the panel makes it weaker and more difficult to install.

| Standard “W” Deck | Inverted/Reversed “W” Deck |

|

|

Installation of Inverted/Reversed Metal Decking

It is important to understand that even if the metal decking is installed upside down it is bundled and shipped right side up from the factory or supplier. This means that during the shakeout process (spreading the metal deck) every sheet must be manually turned upside down. After the metal deck is installed, the sidelaps of the sheets need to be attached together.

Sidelap Attachment For Inverted/Reversed Metal Decking

When you order metal decking that is inverted/reversed you need to make sure you specify the correct sidelap. There are typically 3 different types of sidelaps that can be specified: standard interlocking, stitch-screw, or nestable.

The sidelap attachment method is critical since the metal decking is being installed upside down. This makes some sidelap attachment methods more difficult.

Screw Fastened Sidelap

Stitch Screw Sidelap is a typical callout for attaching the sidelaps of inverted/reversed metal decking. This is because it can be done from the top pretty simply with a screw gun.

Standard Nested Sidelap

Nestable sidelap is attached with stitch screws. Sometimes with form decking, the panel is installed upside down so that they can attach the sidelaps from the top.

Standard Interlocking Sidelap

If the panel has the standard interlocking sidelap, you will discover this is the most difficult to attach in the reversed position. After the metal decking is turned upside down and installed, you will need to go beneath the metal decking to attach the sidelaps. You'd normally use a scissor lift to move around and then lift the button punch tool over your head to attach the sidelaps together.

If the panel has the standard interlocking sidelap, you will discover this is the most difficult to attach in the reversed position. After the metal decking is turned upside down and installed, you will need to go beneath the metal decking to attach the sidelaps. You'd normally use a scissor lift to move around and then lift the button punch tool over your head to attach the sidelaps together.

Bidding A Job With Inverted/Reversed Metal Decking?

If you are responsible for bidding on new construction projects, and the one you have has inverted/reversed metal deck specified, there are a few key things to keep in mind.

- Metal Deck Cost - When you get a quote for the metal decking, you will find out that even if you specify inverted/reversed, the metal decking will come right side up. The critical part you need to make sure you specify is the sidelap attachment. If your job has B nestable for instance, you will find that B deck with a nestable sidelap is a special custom order. It will cost more than your standard B deck, and will take longer to manufacture. However if you are purchasing a typical metal decking panel with a standard sidelap, than the pricing will range from $2.00 to $6.00, depending on the panel, gauge, finish and quantity.

Check out: How Much Does Metal Deck Cost, for a range of metal decking prices. - Lead Time - can range from a few days to weeks depending on whether your panel is readily available from a metal decking supplier or if it needs to be custom manufactured.

Be sure to check with your metal decking supplier on approximate cost and lead time prior to bidding. - Labor - The amount of extra labor is another factor you need to take into consideration. When the metal decking is shipped from the manufacturer or supplier, it is shipped right side up. This means that as your employees are separating the metal decking sheets, they also need to flip them upside down. This may not seem like a ton of extra work, however, metal decking can be long and heavy. So it will take more time to do this extra step. The sidelap attachment will also need to be factored in. If you are dealing with a standard interlocking sidelap where the the sidelaps will need to be connected from underneath, this will take much more time and will require extra equipment.

At Western Metal Deck we have been selling metal decking for over 30 years. Over the years we have had a few customers who ended up installing the metal decking incorrectly. The result? It had to be ripped off, repurchased, and reinstalled.

As you can imagine, these types of mistakes aren’t cheap. Your best strategy when bidding or working on a job with this type of metal deck specified is to familiarize yourself with it and properly budget for it.

Learn more about Metal Decking: Types & Uses