Metal Roof Decking Profiles: B Decking & N Deck

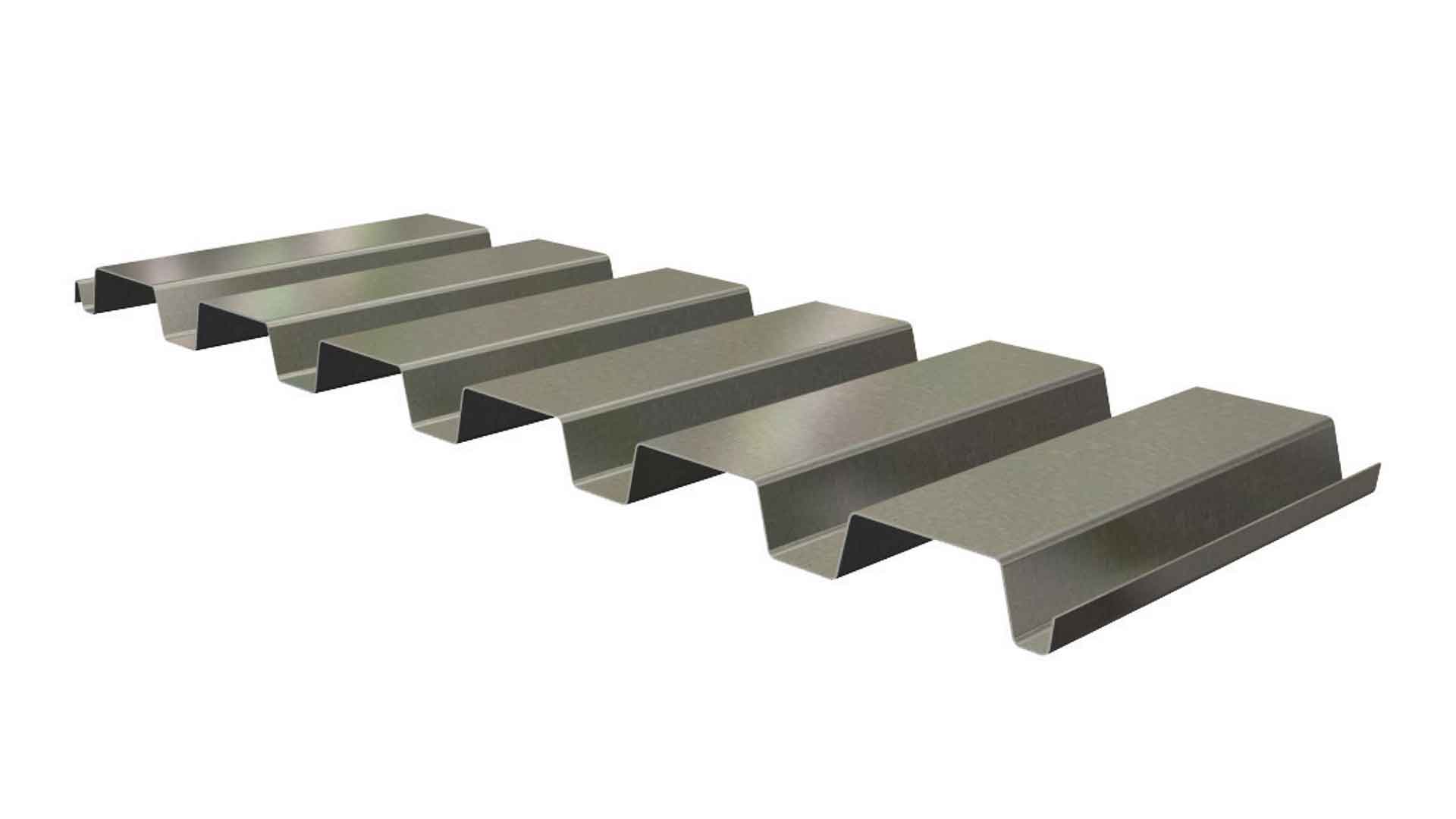

Metal Deck | B Deck | N Deck

When you find yourself with a project that has a call out for metal roof deck, it is important to know your options. Metal roof deck comes in different profiles and each has different dimensions that affect the panels overall strength. A panel that is stronger will span longer distances, but will also cost more. Depending on how far you need your panel to span, will help determine which panel is right for you.

Metal roof deck comes in depths from 1 ½” deep type B to 3” deep type N. It also comes in different gauges and finishes. While the amount of options can be overwhelming, choosing the right type, gauge, and finish comes down to what your project's conditions are.

At Western Metal Deck we stock and sell a wide array of different gauges and finishes. We understand that each project has different requirements so we keep plenty of options on the floor.

In this article we will go over the different types of roof deck, we will go over Type 1.5” B, and Type 3” N. You’ll learn about the profiles, gauges and available finishes that can help you better understand your roof deck options.

What is Type B Roof Deck

|

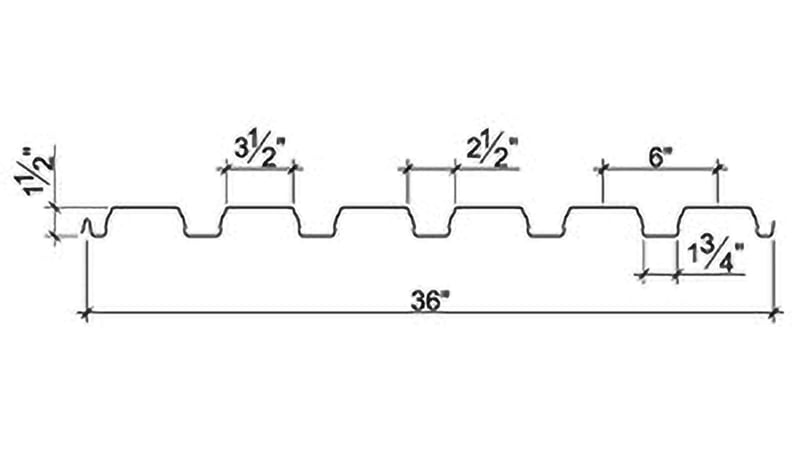

Type B-deck is the most commonly requested metal roof deck panel in the Western United States. It is designed to be a roof deck panel to support built-up roofing, but is also used on trash gates, canopies, awnings, and many more applications. The panel is 1 1/2” Deep and 36” Wide. It is normally used in span conditions under 10 feet. B-deck can go by different names depending on the manufacturer and it’s sidelap connection.

B Deck Gauges

B roof deck can be manufactured in the following gauges: 22, 20, 18, & 16. 22 Gauge is the lightest, weighing 1.9 pounds per square foot. 16 gauge is the heaviest, weighing 3.5 pounds per square foot. The main reason that a heavier gauge would be used is to eliminate sagging due to the distance of the span between beams. The further apart the beams are, the heavier the gauge needs to be in order to span the distance.

| Gauge | Weight Per Square Foot |

| 22 | 1.78 to 1.90 |

| 20 | 2.14 to 2.30 |

| 18 | 2.82 to 2.90 |

| 16 | 3.5 to 3.54 |

Common Names for Type B Roof Deck

You may have heard B roof deck referred to by different names. This is because it is produced by different manufactures, who each have a slightly different name for it. The name also changes based on it’s side lap connection. Below are some of the most common names for B roof deck by manufacturer:

| Verco Decking | Vulcraft |

| HSB-36 | 1.5B |

| PLB-36 | 1.5BI |

| HSB-36-SS | 1.5BA |

| 1.5BIA |

What is Type N Roof Deck

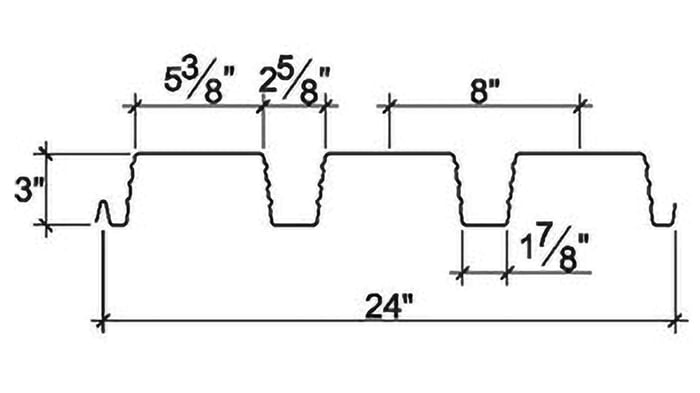

Type N roof deck is a 3” deep panel. Type N is a long span panel, if you have a project that needs to span distances between six to sixteen feet then you may want to consider type N. There are two different types of N roof deck panels. It comes in either a 24” wide panel referred to as N-24 or a 32” wide panel referred to as HSN3-32.

For years Vercor/Vulcraft only had one type of type N deck, which was the 24” wide panel. However, over the years the new wider profile of type N was introduced, the 32” wide variety.

N Roof Deck: Type N-24

Type N-24 is a 3” deep, 24” wide long span panel. The strength of a panel is a component of the depth and the thickness of the panel. The deeper the panel is, the stronger the panel is and the further it can span. Type N-24 can span distances ranging from 6 feet up to 16 feet. It is used in different applications such as roofs, canopies, and awnings.

|

|

N-24 Gauges

Type N-24 is available in thicknesses ranging from 16 Gauge to 22 Gauge. A thicker gauge increases how far type N-24 can span.

| Gauge | Weight Per Square Foot |

| 22 | 2.2 - 2.26 |

| 20 | 2.6 - 2.71 |

| 18 | 3.5 - 3.56 |

| 16 | 4.2 - 4.46 |

Common Names for Type N-24

Depending on the manufacturer and the side lap connection Type N-24 can be referred to by different names. Below are the names it is referred to by Verco and Vulcraft.

| Verco Decking | Vulcraft |

| N-24 | 3N |

| PLN-24 | 3NI |

| N-24-SS | 3NA |

| 3NIA |

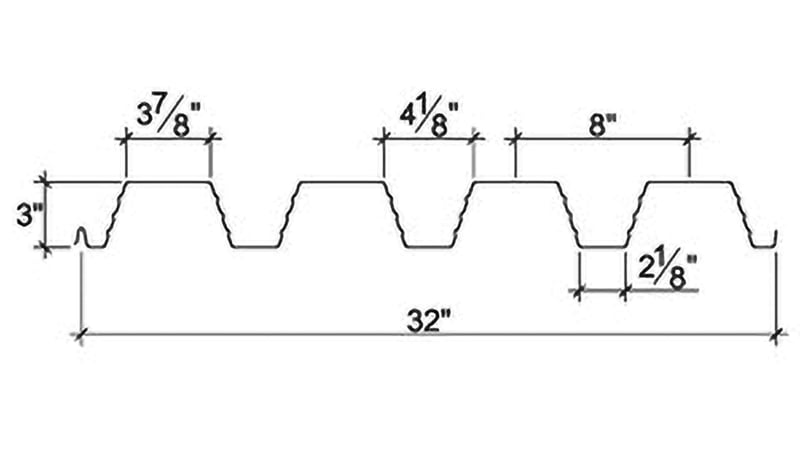

N Roof Deck: Type HSN3-32

|

|

Type HSN3-32 is 3” deep, 32” wide. This metal roof deck panel is an extra 8” wider than its counterpart N-24. It is often viewed as a superior panel over the N-24. It is still capable of spanning long distances due to the 3" depth, however it is an easier panel to handle over type N-24.

The extra 8” of width makes it an easier panel to install over the N-24. It takes less sheets to cover an area using HSN3-32. For instance to cover an area that is 100 feet wide, it would take 38 sheets of type HSN3-32 vs 50 sheets of type N-24. As you can imagine, on a project with tens of thousands of square feet the difference in the amount of sheets to cover an area can add up. Using less sheets means fewer bundles to handle, faster installation, as well as fewer side laps to connect.

Gauges for Type HSN3-32

As with the other available roof decks, type HSN3-32 is available in thicknesses ranging from 22 to 16 gauge.

| Gauge | Weight Per Square Foot |

| 22 | 1.8 - 2.0 |

| 20 | 2.2 - 2.4 |

| 18 | 2.9 - 3.1 |

| 16 | 3.7 - 3.9 |

Common Names for Type HSN3-32

Depending on the sidelap connection and manufacturer you may have heard type HSN3-32 referred to by other names such as the ones listed below.

| Verco Decking | Vulcraft |

| HSN3-32 | 3NL-32 |

| PLN3-32 | 3NI-32 |

| HSN3-32-NS | 3PLN-32 |

| HSN3-32-SS | 3NIA |

Roof Deck Finishes

The most common finish for all metal roof deck is Galvanized G-60. This is the finish you will find most readily available in stock. Roof deck is also available with the option of different finishes, such as Prime Painted or Galvanized G-90 (which is a heavier galvanizing than G-60). However, you will need to plan ahead as some of these are not readily available and require an average of 3 to 4 week lead time.

While you will find that a Galvanized G-60 finish is much more common to find, on rare occasions where the decking is subjected to humidity or rain water Galvanized G-90 may be chosen as it adds a little extra protection against corrosion. There is not much difference between G-60 and G-90. Galvanized G-60 is 6/10 of an ounce per zinc per square foot, 3/10 on one side and 3/10 on the other side. Galvanized G-90 is 9/10 of an ounce of zinc per square foot, 4.5/10 on one side and 4.5/10 on the other side.

Prime painted roof decks are not normally used except on very large warehouses where they are looking to save a few cents per square foot. The prime paint is applied over cold rolled steel without any galvanizing, rusting is not normally a problem since a built up roof is put over the metal deck to protect it from the elements. On projects of over a 250,000 square feet a few cents starts to add up to a lot of money. However on a project of a few thousand square feet, it doesn’t add up to much.

For more information on metal deck finishes check out:

Different Types of Metal Decking Finishes (+Lead Times)

Which Roof Deck Panel Is Right For You?

The right roof deck panel for you depends on the job requirements. If you already have a type specified on the structural plans, then you will need to use that specific type.

- If you are looking for a long span panel, then you may want to consider type N.

- If you are only needing something for short span conditions and are trying to save money, then type B may be right for you.

Whichever panel you decide to go with, you will need to have the engineer approve it to make sure it will work on your job.

Once you have decided on which panel is right for you, your next step is knowing what gauge, finish, and sidelap connection you will need. At Western Metal Deck we stock Verco roof deck with standard interlocking sidelap in 16 to 22 gauge in Galvanized finishes.

For more information on sidelap connections check out:

The Most Common Metal Deck Sidelap Types & Connections