How Much Does My Metal Deck Weigh?

This is a question we get asked often and it’s one that you are probably asking yourself. You need to know how heavy your bundles are or if your truck can even pick up the metal deck.

You already know that the gauge of your metal deck is a big factor in the weight, but why does weight vary between panels of the same size? Why exactly do two different types of metal deck with the same gauge have a different per square foot weight?

To answer this, it helps to understand the metal deck manufacturing process. We will go over this process, what metal deck weighs, and why the weight is important to you.

At Western Metal Deck we calculate the weight of metal deck daily. We use the weights to figure out bundle weights to what size truck we need to use for deliveries.

This article will help you understand the factors that impact how much your metal deck will weigh. We will cover the following:

- Metal Deck Coils

- Types of Metal Deck

- How to Calculate the Total Weight

- Weight of Metal Deck Bundles

Metal Deck Coils

The metal deck process begins with the steel. Steel is made into steel coils, which is used to produce metal deck. If you are familiar with steel coils then you know that it is a long steel sheet that has been rolled up into a coil. The coils come in different thicknesses and widths.

Thickness of Coil

The thickness of the coil refers to the thickness of the steel sheet. This thickness is how the gauge is determined. Every gauge of metal falls within a specific range of thicknesses. For example 16 Gauge metal is within 0.0695 to 0.0575 inches thick.

Width of Coil

The width of the coil varies from panel to panel. The steel coils are roll-formed into the different corrugated metal deck panels. Due to the panels varying in widths, depths, and corrugations they aren’t all produced out of the same width coil. If a profile has more corrugations, deeper corrugations, or wider corrugations, you’ll need a wider coil.

The different width coils will directly impact the weight of the panel per square foot. If you have 2 panels the same gauge, but are made from 2 different width coils, the weight per square foot will be different. An example of this can be seen when comparing W2-36 Formlok and W3-36 Formlok:

|

|

| W2-36 Formlok | W3-36 Formlok |

Both panels are 3’ wide and look similar. However, the W3-36 is deeper and manufactured out of a wider coil then the W2-36. The weight per square foot for a 20 Gauge Galvanized panel in W2-36 is 2.1 pounds per square foot and the W3-36 is 2.3 pounds per square foot.

Weight For Types of Metal Deck

As you have come to learn metal deck comes in different types: roof, floor, form, and cellular. It is possible to have two different panel types of the same gauge that weigh the same per square foot. Meanwhile, two other types of panels that are the same gauge can weigh drastically different. There are a few different reasons for this, which we will go over.

Metal Roof & Metal Floor Deck Weight

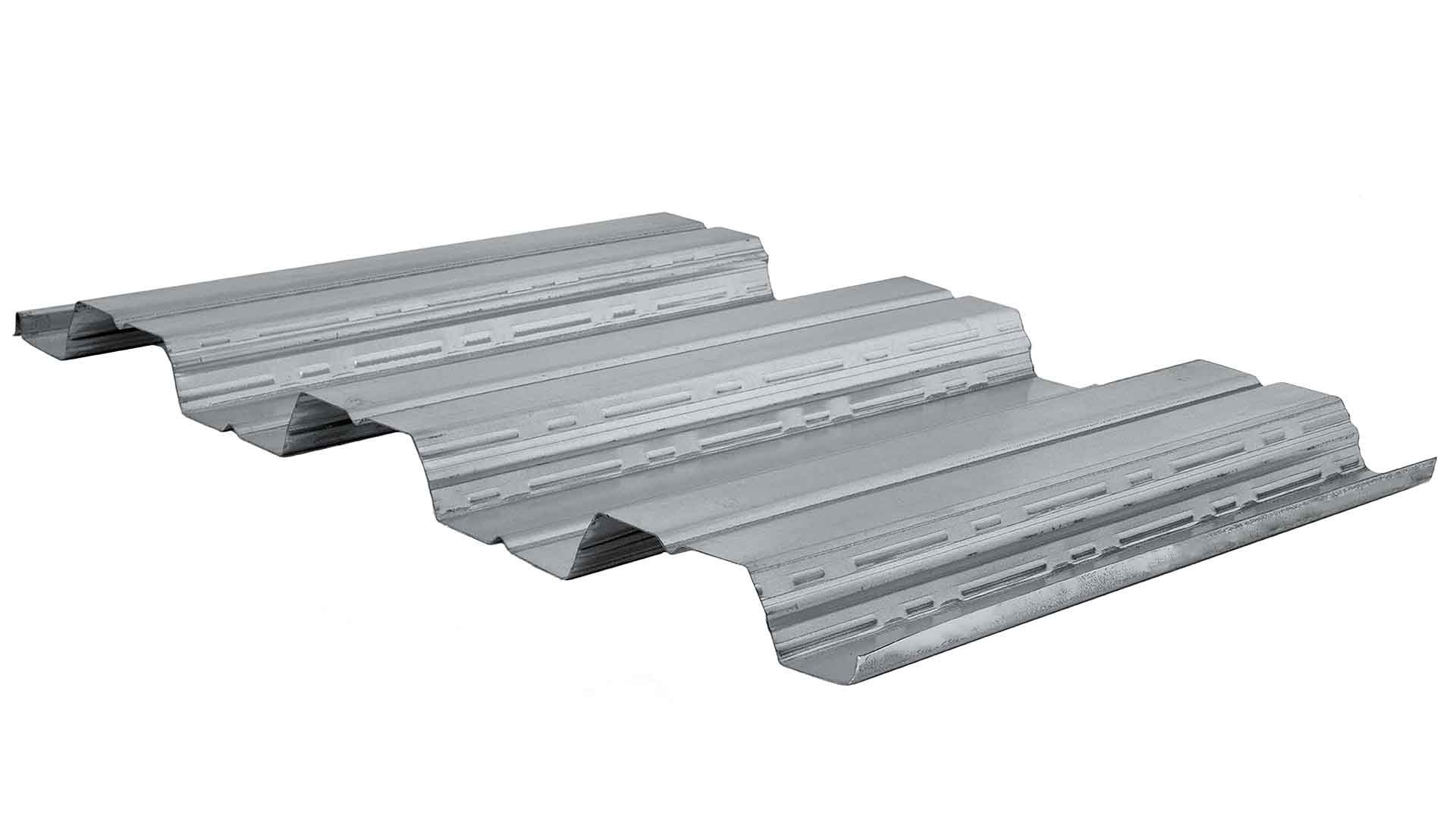

Metal roof and floor deck are two completely different types of decking panels. They come in panels that are 1.5” deep to 3” deep in gauges ranging from 22 to 16, in different profiles. Some roof deck profiles are identical to some floor deck profiles minus the embossment pattern.

An interesting thing to note is that the embossment pattern does not affect the weight whatsoever. Both panels are manufactured out of the same coil. During the roll-forming process, the embossment pattern gets stamped onto the floor deck panels.

| ROOF | HSB-36 | N/A | N/A | ||

| FLOOR | B-36 Formlok | N-24 Formlok | N3-32 Formlok | W2-36 Formlok | W3-36 Formlok |

| Weight per Sq. Ft. | Weight per Sq. Ft. | Weight per Sq. Ft. | Weight per Sq. Ft. | Weight per Sq. Ft. | |

| 22 Gauge | 1.9 | 2.2 | 2.0 (roof only) | 1.8 | 1.9 |

| 20 Gauge | 2.3 | 2.6 | 2.4 | 2.1 | 2.3 |

| 18 Gauge | 2.9 | 3.5 | 3.1 | 2.7 | 2.9 |

| 16 Gauge | 3.5 | 4.2 | 3.9 | 3.3 | 3.5 |

Metal Form Deck Weight

Form deck, or Non-Composite deck, comes in a couple of different profiles. The weight varies by the profile type and the gauge. We stock Verco Decking, they manufacture two profiles: 1 5/16” Deep Vercor and 9/16” Shallow Vercor. The Deep Vercor is manufactured out of a wider coil and weighs more per square foot.

| Deep Vercor | Shallow Vercor | |

| Gauge | Weight per Sq. Ft. | Weight per Sq. Ft. |

| 26 | 1.1 | 1.0 |

| 24 | 1.4 | 1.3 |

| 22 | 1.7 | 1.6 |

| 20 | 2.1 | 1.9 |

Cellular Deck Weight

The weight of cellular decking may surprise you, as it can be pretty heavy. Cellular decking is a metal deck panel in one gauge with a flat sheet in the same or different gauge attached to the bottom of the panel.

| ROOF | HSBCD | NCD-24 | HSN3CD | N/A | N/A |

| FLOOR | BCD-36 Formlok | NCD-24 Formlok | N3CD-32 Formlok | W2CD-36 Formlok | W3CD-36 Formlok |

| Weight per Sq. Ft. | Weight per Sq. Ft. | Weight per Sq. Ft. | Weight per Sq. Ft. | Weight per Sq. Ft. | |

| 20/20 Gauge | 3.6 | 4.1 | 3.9 | 3.4 | 3.6 |

| 20/18 Gauge | 4.1 | 4.6 | 4.4 | 3.8 | 4.0 |

| 18/20 Gauge | 4.1 | 4.8 | 4.6 | 3.9 | 4.1 |

| 18/18 Gauge | 4.6 | 5.3 | 5.1 | 4.3 | 4.6 |

| 18/16 Gauge | 5.1 | 5.8 | 5.7 | 4.8 | 5.0 |

| 16/18 Gauge | 5.3 | 6.1 | 5.9 | 4.9 | 5.2 |

| 16/16 Gauge | 5.8 | 6.6 | 6.4 | 5.4 | 5.7 |

Optional Features

Metal deck has a few different optional features that you can choose from. The two main ones that you need to familiarize yourself with are sidelap connections and vent tabs.

Metal roof and floor deck can be manufactured with a couple of different sidelaps, either a standard interlocking or a stitch-screw sidelap. The sidelap that you choose doesn’t impact the weight per square foot. The panel gets manufactured out of the same width coil.

Vent tabs are another optional feature that we occasionally see specified on floor decks. These vent tabs are creating by puncturing the deck and creating a vent. Vent tabs are made during the manufacturing process. Just like embossments and sidelaps, no extra weight is incurred. The panel weighs the same with or without the vent tab.

How to Calculate The Total Weight Of Metal Deck

So now that you know how much your metal deck weighs, you can begin to calculate the total weight of your metal deck.

The process to calculate the weight of a panel is pretty simple:

Multiply the Weight Per Square Foot X Width of Panel X Length of Panel = Weight of Panel

If you have more than one panel in a bundle and they are all the same length then:

Multiply the weight of the panel X # of pcs = Weight of the bundle.

Example:

Total weight for: 20 GA HSB-36, 10 sheets @ 22’-0” long

2.3 (weight per square foot) X 3 (width of panel) X 22 (length of panel) = 151.8 pounds per panel

151.8 X 10 = 1,518 pounds Total Weight

Why Does The Weight Of Metal Deck Bundles Matter?

One reason that you need to know how much your metal deck weighs is for bundling purposes. You normally wouldn’t purchase 1 or 2 sheets of metal deck, unless it was to finish up a job. Typical jobs require more than 15 pieces of deck. Telling your metal deck supplier how you want your metal decking bundled can prove very beneficial when the decking gets to the jobsite.

See how to bundle a job and make a bundle location plan.

In order to make a bundling list, your bundle of decking cannot exceed 4,000 pounds. That number may seem like a lot, but a heavy gauge decking in long lengths easily gets over 4,000 pounds in a matter of just 10 sheets.

Another important reason to know how much your metal deck weighs is to determine what size truck you need to pick up in. Metal deck bundles can get quite heavy. If you pick up in too small a truck you will have to either make multiple trips or send a whole other truck.

At Western Metal Deck we don’t like to see our customers waste time. We offer delivery to your shop or jobsite to eliminate the hassle of having to figure out how to get the metal deck to its destination. All you have to do once the metal deck arrives is take it off the truck.